Home / Solutions / Food industry / Premix-Beef Bone Meal Screening Solution

●After coming out of the grinder, it enters the primary cleaning screen through screw conveying. There are residual materials in the screw, resulting in incorrect material proportioning;

● The primary cleaning screen can only be installed with a punching plate. The aperture of the mesh is generally >4mm. If it is <4mm, the productivity of the primary cleaning screen will be too low;

● There was no screening equipment designed in the customer’s process, resulting in substandard quality of the finished product.

Original production process flow: tons of packaging raw materials → screw conveyor → primary cleaning screen → iron remover → temporary storage warehouse → packaging machine

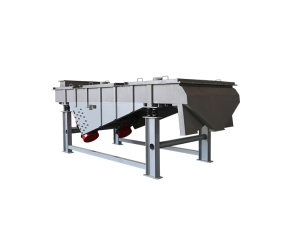

The rectified process flow: tons of packaging raw materials → grinder → linear screen → temporary storage warehouse → packaging machine

Premix-Main Problems in Beef Bone Meal Screening

● After coming out of the grinder, it enters the primary cleaning screen through screw conveying. There are residual materials in the screw, resulting in incorrect material proportioning;

● The primary cleaning screen can only be installed with a punching plate. The aperture of the mesh is generally >4mm. If it is <4mm, the productivity of the primary cleaning screen will be too low;

● There was no screening equipment designed in the customer's process, resulting in substandard quality of the finished product.

Hemeihua Group Co., Ltd.

Jinan Jiabao Dairy Co., Ltd.

Guangzhou Chengyi Biological Co., Ltd.

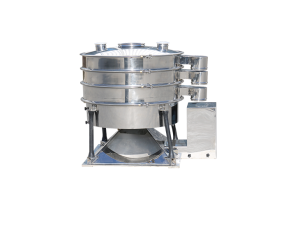

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It has unique effects on the screening and classification of powdery and granular materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)