Glass products are almost everywhere in every corner of life. The country’s waste glass can reach 50 million tons every year. Whether it is beer bottles, water glasses, etc., they are consumed and discarded after use. After crushing these waste glasses, they are made into building materials. Bricks, reflective board materials, decorations, pavement assemblies, etc. are widely used and in high demand, so there is no need to worry about running out of sales.

The benefits generated by the waste glass processing production lines on the market today can only achieve “13% reuse of waste glass”. Simple coarse crushing and fine crushing have a limited usable range. However, in Shanghai, Henan, Zhejiang and other places, the waste glass is not recycled. The glass processing recovery rate reaches 30.5%.

For waste glass crushing, you only need to add grinding equipment after the crushing production line, and the reuse value will be doubled. The finished products can be used in a wider range and the price is higher. The following are several sales channels:

1. Particles >5mm: The mixture of waste glass and plastic waste can be molded into slate products with hard texture and good-looking appearance.

2. Particle size > 10mm: It has a wide range of applications and can be used as pavement combinations, building bricks, glass wool insulation materials and honeycomb structural materials.

3. Particle size 0.5-3mm: Waste glass ground into powder can be used to make reflective board materials and decorations for clothing.

Waste glass

Finished glass particles

It is widely used in more than ten related industries such as aerospace, railways, decorative construction, home furniture, advertising displays, craft gifts, building materials and sanitary ware, yacht parking, sports materials, sanitation projects, etc. Made into building bricks, reflective board materials, decorations, pavement assemblies, etc.

Structure

Railway

Water Conservancy

Highway

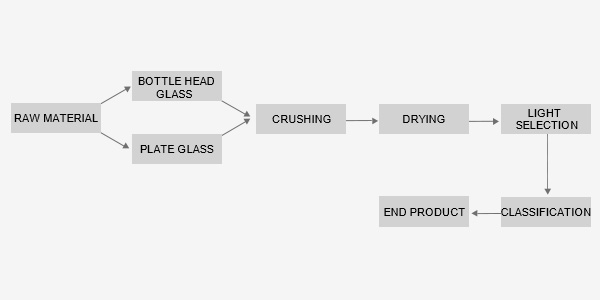

Waste glass is a brittle material. The production line is divided into two schemes: wet crushing and screening and dry crushing and screening. The equipment mainly consists of crusher, bar screen, probability screen, linear screen, water washing equipment, dehydration screen, etc. The two schemes are as follows:

Dry screening

Wet screening

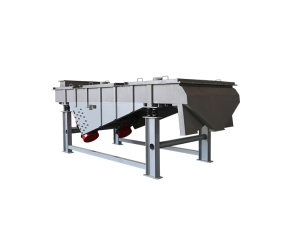

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

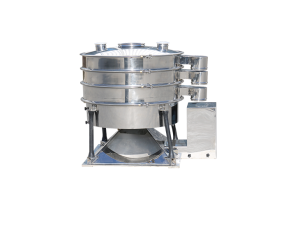

It has unique effects on the screening and classification of powdery and granular materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)