Home / Solutions / Chemical industry / Titanium dioxide

Titanium dioxide is also called titanium dioxide. Its chemical formula is: TiO2. It has stable chemical properties and does not react with most substances under normal conditions. Titanium dioxide is widely used.

Screening mesh size: 40-325 mesh or even finer;

Material characteristics: white crystal or white crystal powder, easy to block the network and absorb moisture.

Titanium dioxide is also increasingly used in cosmetics. Since titanium dioxide is non-toxic and far superior to lead white, titanium dioxide is used in almost all kinds of fragrance powders to replace lead white and zinc white. Just add 5%-8% titanium dioxide to the fragrance powder to get a white color, making the fragrance smoother, with adhesion, absorption and covering power. In gouache and cold cream, titanium dioxide can reduce the greasy and transparent feeling. Titanium dioxide can also be used in various other fragrances, sunscreens, soap flakes, white soaps and toothpastes.

Cosmetic-grade titanium dioxide is divided into oil-based and water-based titanium dioxide. Because of its stable chemical properties, high refractive index, high opacity, high covering power, good whiteness, and non-toxicity, it is widely used in the field of cosmetics for beauty and whitening effects.

Titanium dioxide for coatings is divided into two types: anatase type and rutile type. Anatase titanium dioxide and rutile titanium dioxide have different structures and are used in different places. Anatase type titanium dioxide is used in interior wall coatings because it is easy to powder, while rutile type titanium dioxide is often used in exterior wall coatings because of its aging resistance. They all have a stable crystal lattice and are important white pigments and porcelain glazes. Compared with other white pigments, they have superior whiteness, tinting power, hiding power, weather resistance, heat resistance, and chemical stability, especially no toxicity.

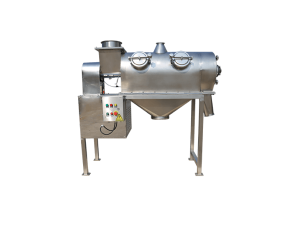

Since the selection of vibrating screen should include many factors such as: particle size structure, specific gravity, moisture content, viscosity, temperature, processing capacity, etc., you can choose the following models for screening titanium dioxide:

1. Rotary vibrating screen (small output, high precision)

2. Linear vibrating screen (the output and precision are not as good as the rotary vibrating screen)

3. Ultrasonic vibrating screen can achieve a certain particle size distribution in fine selection, making the particle size uniform and fine. It is used as a colorant in the rubber industry and has the functions of reinforcement, anti-aging and filling. Adding titanium dioxide to white and colored rubber products makes them resistant to sunlight, no cracking, no discoloration, high elongation and acid and alkali resistance when exposed to sunlight. Titanium dioxide for rubber is mainly used in automobile tires, rubber shoes, rubber floors, gloves, sports equipment, etc., and is generally anatase type. However, when used in automobile tire production, a certain amount of rutile products are often added to enhance ozone and ultraviolet resistance.

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

When two vibrating motors installed longitudinally on the screen body run relative to each other, the horizontal excitation forces generated by them cancel each other out due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the materials on the screen surface are subject to the excitation force and jump on the screen surface in the direction of the discharged product. The materials smaller than the screen hole fall to the lower layer through the screen hole, and then jump from The discharge port flows out. Due to the reasonable screening process, after the materials are classified by the vibrating screen, several materials with different particle sizes can be obtained to complete the material classification operation.