Sugar is a condiment processed from plants such as sugar cane or beet, and its main ingredient is sucrose. Guangxi, Yunnan, Guangdong, Hainan, Fujian, Taiwan and other provinces, as well as Xinjiang and Northeast China are the main sugar-producing areas in my country. Sugar is an important condiment, which can increase the sweetness and umami of dishes and the color of products. It is the main seasoning raw material for making dishes, especially beet varieties.

Sugar is a condiment processed from plants such as sugar cane or beet, and its main ingredient is sucrose. Guangxi, Yunnan, Guangdong, Hainan, Fujian, Taiwan and other provinces, as well as Xinjiang and Northeast China are the main sugar-producing areas in my country. Sugar is an important condiment, which can increase the sweetness and umami of dishes and the color of products. It is the main seasoning raw material for making dishes, especially beet varieties.

Granularity of sugar

There are four grades: Refined, Superior, First Class and Second Class

Coarse Grain:0.800~2.50mm

Large Grain:0.630~1.60mm

Medium Grain:0.450~1.25mm

Fine Grain:0.280~0.800mm

1. The grains are uniform and the grain size should not be less than 80% within the following range.

2. The grains or its aqueous solutions are sweet and have no peculiar smell.

3. Dry and loose, white, shiny, no obvious black spots.

Classification of sugar

A、Raw sugar

Using sugar cane and beet to extract sugar juice, after simple filtration, clarification, boiling concentration and center separation to form sugar crystals. Light brown in color. Sometimes a little molasses or water. It is the most important sugar product in international trade. Raw sugar is only used as a raw material for sugar refining and cannot be directly added to food or eaten directly.

B、White sugar

Using sugar cane and beet as raw materials (one-step method) or raw sugar (two-step method), through juicing, filtration, impurity removal, clarification (the above steps are not required for raw sugar), vacuum concentration, boiling, de-honey, washing Sugar, obtained after drying. White granulated sugar is the most important variety of edible sugar. In foreign countries, basically 100% of edible sugar is white granulated sugar. In China, white granulated sugar accounts for more than 90% of the total edible sugar. White sugar is divided into refined, superior, first-class, second-class.

C、Soft white sugar

as raw materials (beets are also directly produced in Xinjiang and other places), which are recrystallized after dissolving. Soft white sugar is a kind of edible sugar that domestic consumers prefer. Its texture is soft and delicate, with small crystal particles, and about 2.5% invert syrup is sprayed in the production process, so the taste is sweeter than granulated sugar. There are three grades of soft white sugar: refined, premium and first-class.

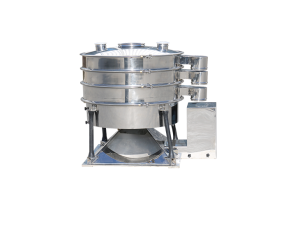

Screening requirements for white sugar

The screening of white sugar is mainly for impurity removal and classification, and the output is 1-50 tons.

Impurity removal: 8 meshes, 10 meshes

Grading: 40 mesh, 60 mesh

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

When two vibrating motors installed longitudinally on the screen body run relative to each other, the horizontal excitation forces generated by them cancel each other out due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the materials on the screen surface are subject to the excitation force and jump on the screen surface in the direction of the discharged product. The materials smaller than the screen hole fall to the lower layer through the screen hole, and then jump from The discharge port flows out. Due to the reasonable screening process, after the materials are classified by the vibrating screen, several materials with different particle sizes can be obtained to complete the material classification operation.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)