Soy protein isolate is extracted from soybeans through a series of processing steps, and then obtain a near-purified protein. Soy protein isolate contains eight essential amino acids, similar with meat, fish, eggs, milk, belonging to the full price of protein. Research shows that protein is the material basis of life and is one of the three major components of human body. The lack of protein can directly lead to growth retardation, low immunity, loose skin and premature aging. In the many plant-based proteins, the most nutritious is legume protein (also known as soy protein), and legumes contain no cholesterol, which the characteristic of animal foods don’t have. Soy protein has its drawbacks without any processing: the content of methionine (an essential amino acid) is relatively low. Therefore, whole soybeans have an amino acid score of approximately 0.6-0.7. However, due to the high protein content of soybeans and the absence of cholesterol, soy protein flour is widely used.

Material properties

Soy protein isolate is extracted from soybeans through a series of processing steps, and then obtain a near-purified protein. Soy protein isolate contains eight essential amino acids, similar with meat, fish, eggs, milk, belonging to the full price of protein. Research shows that protein is the material basis of life and is one of the three major components of human body. The lack of protein can directly lead to growth retardation, low immunity, loose skin and premature aging. In the many plant-based proteins, the most nutritious is legume protein (also known as soy protein), and legumes contain no cholesterol, which the characteristic of animal foods don’t have. Soy protein has its drawbacks without any processing: the content of methionine (an essential amino acid) is relatively low. Therefore, whole soybeans have an amino acid score of approximately 0.6-0.7. However, due to the high protein content of soybeans and the absence of cholesterol, soy protein flour is widely used.

Production process

Leaching process, acid precipitation separation process, the neutralization process, flash evaporation process and drying process, the dried soy protein powder need to carry out the final impurity removal, it can be packaged after sieving pine.

Screening purpose

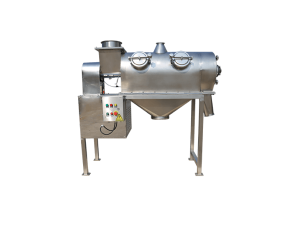

This screening and impurity removal process is to play a protective role, remove the impurities, caking from the soy protein powder, but also has the role of loose materials to ensure the purity of semi-finished soy protein powder raw materials

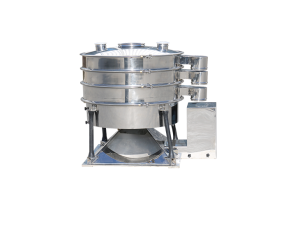

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying