Home / Solutions / Food industry / Sodium chloride(Industry salt)

Types of salt

1. According to whether it is edible, it can be divided into industrial salt and edible salt;

2. According to the production process, it can be divided into: sea salt, mineral salt and vacuum salt;

3. According to the use, it can be divided into: industrial salt, feed salt, snow melting salt, health salt, pickling salt and edible salt.

1. Screening material name: industrial salt (for feed additives);

2. Screening mesh: 10 mesh (2.0mm) or 8 mesh (2.23mm);

3. Screening output: 40-45 tons / hour;

4. Screening purposes: to remove the caking from salt;

5. The production process: vacuum salt making --- wet salt screening --- Belt Conveyor --- hopper --- Drying ---- Belt Conveyor --- Silo ---- Screening - ---package

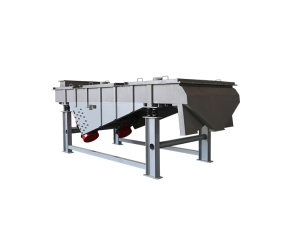

6. The customer designated models: round vibrating sieve;

Vacuum salt making evaporation process is based on brine as the raw material by four-effect evaporation (evaporation tank), advection feed, downstream row of salt and external heating forced circulation evaporator evaporation crystallization of crude salt. The part of the leaves of the wood leaves is transferred to a nitrification tank after being preheated in three stages, and the brine is heated to evaporate and precipitate in a nitrification tank. The mother liquid flows into the flash tank by the pressure difference and makes full use of the residual heat after the steam is condensed, Pressure difference under the effect of flashing steam;

1. Screening mesh: 10 mesh or 8 mesh;

From the screening of customer requests, we need to understand the purpose of screening customers firstly, the real demand? Why the screen mesh is 10 mesh? In general, 10 mesh screening is for impurity removal, through communication with customers, we understand that the purpose of screening to remove caking on the belt, and customers have screened salt 6mesh after dried , the purpose of this screening is mainly to prevent caking or foreign objects generated in the conveyor process;

2. Screening output: 40-45 tons / hour;

We suggest two sets of SZF-1225 linear vibrating screen will up to outputs.

3.Customer's production process: vacuum brine salt making- crystallization - wet salt conveyor --- drying --- screening --- conveyor --- screening

01. Belt conveyor: wet salt and dry salt conveyor by top to bottom belt conveyor, into the different silo; Because the belt conveyor the salt continuous, so the belt have agglomeration and finished product together into the finished product warehouse;

02. After the industrial salt is dried, it is conveyor to the finished silo through the belt conveyor and then into the packing machine;

03. The bags are 50 kg of packaging can not meet the needs of large-volume customer in the site customers, so we would like to transform some of them into tons of bags;

04. To modify the program for on-site measurement according to the customer's request , it is need to size measurement the part of the material inlet and outlet connected to the screen, it is easy to connect up and down; equipment inlet and outlet size measurements on the placement , and inform customers that those parts do not measure. Those parts need to make changes; we need to ask clearly about the customer needs to connect the upper and lower parts .

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It has unique effects on the screening and classification of powdery and granular materials.