Home / Solutions / Food industry / Siraitia grosvenorii powder

Utilizing the pure sweet ingredients contained in Siraitia grosvenorii, a powdered product is extracted. Siraitia grosvenorii extract is a powdered fruit extract with a pure taste and no aftertaste.

Its sweetness is 150-200 times that of sugar. It is formulated in a convenient, concentrated powder form and can be used in a wide range of foods and beverages to reduce sugar usage or replace sugar.

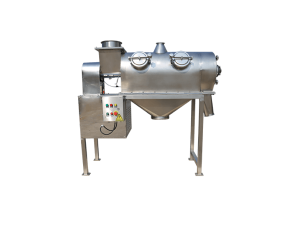

The screening purpose of siraitia grosvenorii powder vibrating screen is to remove large particles, improve product quality, and ensure product quality before packaging. As Siraitia grosvenorii powder is easy to absorb moisture and sticky, the screen is pasted with ordinary rotary vibrating screen. Ultrasonic vibrating screen is required for screening

Utilizing the pure sweet ingredients contained in Siraitia grosvenorii, a powdered product is extracted. Siraitia grosvenorii extract is a powdered fruit extract with a pure taste and no aftertaste.

Its sweetness is 150-200 times that of sugar. It is formulated in a convenient, concentrated powder form and can be used in a wide range of foods and beverages to reduce sugar usage or replace sugar.

Selection of siraitia grosvenorii → crushing → water extraction → filtration → concentration under reduced pressure → spray drying → screening → packaging

1. Siraitia grosvenorii extract is used in traditional Chinese medicine for cold, cough, sore throat, gastrointestinal discomfort, and blood clearing.

2. Siraitia grosvenorii extract is easily soluble in water and does not precipitate. The extract contains 80% or more mogrosides. Sweet glycosides are 300 times sweeter than sugar and low in calories. It is a stable and non-fermentable ideal additive for diabetic patients.

3. Siraitia grosvenorii contains a lot of amino acids, fructose, vitamins and minerals. It is also used as a spice and nutritional additive in traditional Chinese cooking.

As a universal green sweetener, it is an ideal substitute for artificial sweeteners such as aspartame. It can be fully utilized in beverages, baked goods, nutritional foods, low calorie foods, or other foods that require low or no carbohydrate sweeteners or low or no calories.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying