After the waste tires are initially crushed and pulverized, they become granular coarse powder. After passing through a small steel mill, the powder ground out can reach a fineness of 60 mesh or 80 mesh. Coarse-grained rubber powder is easy to screen with a linear sieve, but the fine powder ground out by steel mill is not easy to screen because the rubber powder itself is too fine and elastic. If you use a traditional linear sieve, it will easily block the screen. The output of the centrifugal screen is low and the accuracy is not high. Choosing a rubber powder screening machine with large output without centrifugal screen has become a major problem for rubber powder manufacturers.

Screening problem

After being crushed and pulverized for the first time, the used tires become granular coarse powder. After grinding through a small mill, the powder can be ground to a fineness of 60 mesh and 80 mesh. The coarse-grained rubber powder is well sieved with a linear vibrating sieve, but the fine powder that has been milled by mill is not well sieved because the rubber powder itself is too fine and elastic. If the traditional linear vibrating sieve is easy to block the mesh, the centrifugal sifter has low output and low precision, and the rubber powder sieving machine with large output is not a big problem in the production of rubber powder manufacturers.

Rubber powder vibrating sieve features

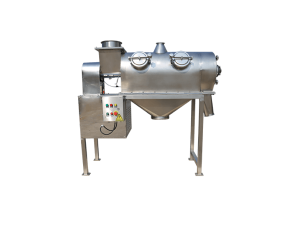

In response to the above problems, our engineers developed a set of centrifugal sifter that specifically screen 60-mesh, 80-mesh fine rubber powder. The benefit of this machine is:

Working principle

The milled material out by the mill is transported to the inlet of the centrifugal sifter through negative pressure, and the material and air are mixed into the vertically installed barrel type, the middle of the screen, and the wind turbine blade passing through the center of the sifter is rotated at a high speed, produce sufficient centrifugal force to spray the qualified material through the mesh. The fine powder passing through the mesh is collected by the cyclone collector. The coarse material that cannot pass through the net can be taken from the automatic slag discharge port to achieve the purpose of rapid screening. The whole system is sealed, dust-free and saves manpower.

Application field

Rubber powder is widely used in sports plastic sports fields, playgrounds, rubber floor tiles, waterproof membranes, waterproof coatings, road modified asphalt, rubber products and other fields.

Tire

Waterproof building materials

The highway

Plastic runway

1. The huizhou city.with its pliasant new tengda waste tyre crushing plant

2. Cangxian hundred million fine powder co., LTD

3. Cloud dream new develop renewable rubber powder co., LTD

4. Hebei tianshun rubber products co., LTD

5. Sichuan cooperates fine car assembly systems co., LTD

6. Sichuan chongqing LeiYuFu

If you could be at screening questions confused, please contact us, allows you to easily solve the problem of screening, and let your product in an impregnable position in the market competition.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

The air flow screen in the air path adopts a closed design. After screening rubber additives, light calcium and other materials, the measured output is 1 ton/㎡/H, the screening efficiency is over 95%, and the dust content in the air is less than 10 mg./m³, which solves the problem of dust flying