Home / Solutions / Metallurgical Industry / Metal powder

Metal powder refers to a group of metal particles having a size of less than 1 mm. Including single metal powder, alloy powder and certain refractory compound powders with metallic properties are the main raw materials for powder metallurgy. Metal powder is divided into five grades of coarse powder, medium powder, fine powder, fine powder and ultrafine powde customarilyr. The metal powder mainly contains iron, tungsten, molybdenum, copper, cobalt, nickel, titanium, bismuth, aluminum, tin, lead and other powders, and the consumption is about 2/3 of the total output of the metal powder. Metal powder can be used as a raw material for powder metallurgy products, and can also be directly applied.

Introduction of metal powder

Metal powder refers to a group of metal particles having a size of less than 1 mm. Including single metal powder, alloy powder and certain refractory compound powders with metallic properties are the main raw materials for powder metallurgy. Metal powder is divided into five grades of coarse powder, medium powder, fine powder, fine powder and ultrafine powde customarilyr. The metal powder mainly contains iron, tungsten, molybdenum, copper, cobalt, nickel, titanium, bismuth, aluminum, tin, lead and other powders, and the consumption is about 2/3 of the total output of the metal powder. Metal powder can be used as a raw material for powder metallurgy products, and can also be directly applied.

Metal powder screening purpose

Remove impurities from metal powder and accurately grade.

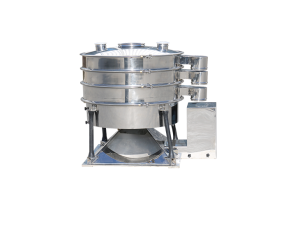

Introduction of Gapfi metal powder sieve

Metallurgical powder special sieve is a clean and environmentally screening device. It is designed to realize a new screening device for removing impurities in metallurgical powder and accurately classifying it under a fully balanced closed condition.

Metallurgical powder special sieve is because the positive pressure airflow generated during the screening process is filtered through the air bag, the air venting window or the equipped dust collector, so that the air pressure inside and outside the screen machine is balanced or even negative pressure; therefore, the powder does not fly. Environmentally, non-polluting; the dust generated by this machine is absolutely below 10mg/m3. Because the ordinary screening machine adopts a simple sealing method that only blocks the air and does not exhaust, the raw material moves to generate heat, and the gas expands and squats in the machine to form a malignant positive pressure gas. Therefore, no matter how tight the ordinary screening machine is, there must be dust.

Gaofu metallurgical powder special sieve features

Metallurgical powder special sieve are widely used in the screening of materials such as molybdenum powder, tungsten powder, nickel powder, cobalt powder and copper powder alloy powder. The main features are as follows:

You don't worry about dust fly , which seriously affects the employee's body.

You don’t worry about throwing raw materials everywhere.

You don’t worry about the lack of precision of the product.

Gaofu Company has used many years of experience in metallurgical powder screening to cooperate with a number of patented technologies to solve your problem.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It has unique effects on the screening and classification of powdery and granular materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)