Home / Solutions / Metallurgical Industry / Iron powder

An aggregate of iron particles with a size less than 1mm. Colour: Black. It is the main raw material for powder metallurgy. According to the particle size, it is customarily divided into five grades: coarse powder, medium powder, fine powder, micro-fine powder and ultra-fine powder. Iron powder composed of particles with a particle size in the range of 150 to 500 μm is called coarse powder, 44 to 150 μm is medium powder, 10 to 44 μm is fine powder, 0.5 to 10 μm is extremely fine powder, and less than 0.5 μm is ultrafine powder. pink. Generally, powder that can pass the 325-objective sieve, that is, the particle size is less than 44 μm, is called sub-sieve powder. If you want to carry out higher-precision screening, you can only use airflow classification equipment, but for some easily oxidized iron powder, you can only use JZDF Nitrogen protection classifier is used to do it. Iron powder mainly includes reduced iron powder, atomized iron powder, and cast pig iron powder; they are named due to different production methods.

An important metal powder in the powder metallurgy industry. Iron powder is used in large quantities in powder metallurgy production, accounting for about 85% of the total consumption of metal powder. The main market for iron powder is the manufacture of mechanical parts, and the amount of iron powder required accounts for about 80% of the total iron powder production.

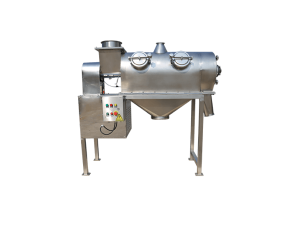

Generally, a rotary vibrating screen can be used for coarse screening of iron powder, but high-precision classification requires an ultrasonic vibrating screen. For grading iron powder that is easily oxidized and explosive, only a nitrogen-protected classifier + an air-tight ultrasonic vibrating screen can be used for high-precision classification.

Iron powder precise grading site

Iron powder precise grading site

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying