Home / Solutions / Lithium battery industry / Artificial graphite

Graphite is the most commonly used to serve as the anode material in lithium-ion battery manufacturing due to its relatively low-cost and its energy density. Graphite has great conductive properties and for the most part is readily available.

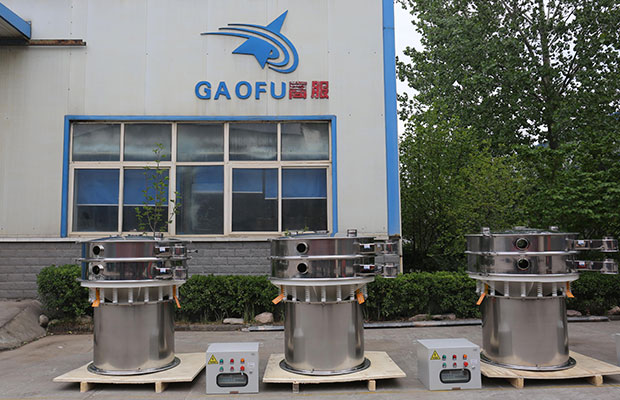

Graphite screening equipment is also called graphite powder screening machine. The graphite screening machine mainly uses ultrasonic waves as the vibration source, which can expand the output.

This is the most common choice for transportation for graphite anodes because they cope well with the flow of lithium ions during charging and discharging. 3 main types of graphite are used in the process; natural, synthetic, and spherical graphite. All have their advantages and disadvantages, but regardless they need to be sieved at fine sizes to work for the industry. Sieving graphite for battery materials can be a tricky process due to the varying shape of graphite. Many of the powder requirements call for it to be below 44 microns and traditional screeners do not have the energy to screen graphite at these sizes.

It has a lighter specific gravity of 0.3-0.8, a fine particle size of D90 below 20 microns, is easy to clump, and has good fluidity.

Screening purpose:

Output: 300kg-500kg

Screening mesh size: 325 mesh-400 mesh

Batch mixing-screening-iron removal-packaging

1. The one-to-four screening system can solve the problem of inability to expand screening output;

2. The quality of the equipment is stable and the equipment is not easily deformed, saving time in cleaning and maintaining the equipment;

3. The quality of our built-in ultrasonic is relatively stable compared to rival products, which can save customers a lot of equipment maintenance costs;

4. Compared with other manufacturers, the difference in output of a single screen machine is negligible. However, other manufacturers mostly use 1-to-2 screening systems, but we recommend using a 1-to-4 screening system to double the output (we use 4 screens, other manufacturers use 2) and the screening accuracy is also higher.

5. The main structure of our screen machine has a long service life.

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.