Home / Products / Conveying and feeding / Vertical Hoist

Scope of application: Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

1.The whole machine has small size, light weight, good sealing performance, low dust and high efficiency.

2.It occupies a small area, is energy-saving and environmentally friendly.

3.It has a large conveying output and has strong adaptability to sheet and granular materials.

4.Simple operation and convenient maintenance.

5.It complies with GMP standards and is easy to clean; it does not cause secondary pollution to materials.

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Carbon black (white carbon black), quartz powder (sand), mica, fluorescent powder, feldspar powder, kaolin, silica black soil, fly ash, glass beads, environmental protection, plastic, plastic, magnetic materials, building materials, mining, kiln industry , feed, condiments, fish meal, rice flour, flour, soybean meal, milk powder, egg powder, starch, sugar, fruit juice, Western medicine powder, Chinese medicine powder, pharmaceutical intermediates, pearl powder, soda ash, polyethylene, resin powder (PVC, ring Oxygen), washing powder, additives, paints, dyes, pigments, rubber, coatings, alloy powder, gold powder, silver powder, copper powder, aluminum powder, nickel powder, chromium powder, magnesium powder, zinc powder, barium powder, vanadium powder, Titanium powder, strontium powder, lead powder, foundry sand, etc.

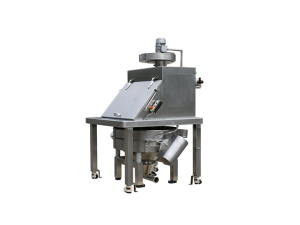

The DZC vertical conveyor uses a vibration motor as the vibration source, and uses the combined amplitude of the two vibration motors to transport materials upward along the spiral conveyor trough. During the vibration process, when the motion acceleration in the direction perpendicular to the bottom of the trough is large enough, the material will break away from the bottom of the trough and fly in the air along a parabolic trajectory until it lands on the bottom of the trough again, thus completing a movement process; the cycle starts again and again, so that the material moves along the spiral groove. Move upward to complete the conveying process. DZC vertical conveyor is mainly used to lift granular, powdery and block materials. This conveyor has a simple structure and is easy to maintain. It can deliver materials in a quantitative manner and the conveying volume is continuously adjustable. It can be used for vertical transportation of small and medium-sized particles in various industries. In addition to lifting materials from bottom to top, it can also complete drying and cooling of materials. effect. It has two structures: trough type and closed type. According to the requirements of different processes, we can design a screening elevator for material particle classification and an elevator for flammable and explosive materials.

The system consists of a feeding platform, dust control, negative pressure system, automatic powder supply, feeding and screening integration

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible