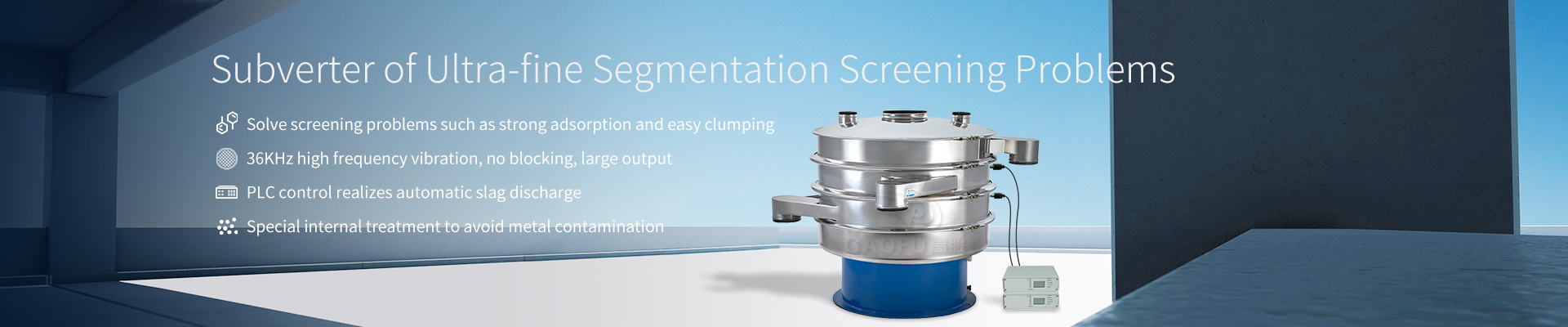

Home / Products / Fine Screening / Ultrasonic Vibrating Sieve

Ultrafine powder sieving:Ultrasonic vibrating sieve suitable for screen separation of powders from 25 microns to 200 microns.

Ensure product cleanliness:Special internal treatment to avoid metal impurity contamination

Automatic slag discharge:PLC control can realize automatic slag discharge

No blocking:36KHz high-frequency vibration, no clogging of the screen, large screening output

Battery materials, silicon materials, food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Lithium iron phosphate, ternary materials, lithium nickel cobalt manganate, lithium nickel cobalt aluminate, lithium manganate, lithium cobalt oxide, lithium hexafluorophosphate, graphite, pole piece recycling, metal microsilica powder, crystalline silicon micropowder, fused silica powder, spherical silica powder, spherical silica, Chinese and Western raw materials, Western medicine, coffee powder, cocoa powder, condiments, food additives, metal powder,copper, iron, aluminum, lead, zinc, alloy powder, magnetic materials, metal powder, alumina , corundum, emery, quartz sand glass powder beads, abrasive materials, plastics, rubber, resins, dyes, fillers, chemicals, activated carbon, wood powder, sawdust, charcoal, fiber materials.

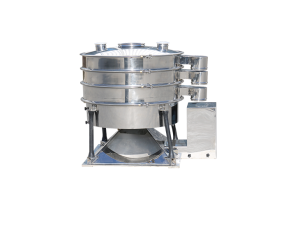

| Model | Dia. (mm) | Area (㎡) | Mesh Size (mesh/”) | Layer (s) | Vibration Motor (kW) | Common Motor (kW) |

| S49-AC-600 | Φ560 | 0.23 | 2-500 | 1-5 | 0.25 | 0.75 |

| S49-AC-800 | Φ760 | 0.42 | 1-5 | 0.55 | 1.1 | |

| S49-AC-1000 | Φ930 | 0.64 | 1-5 | 1.1 | 1.5 | |

| S49-AC-1200 | Φ1130 | 0.95 | 1-5 | 1.1 | 1.5 | |

| S49-AC-1500 | Φ1430 | 1.61 | 1-4 | 1.5 | 2.2 | |

| S49-AC-1800 | Φ1730 | 2.35 | 1-3 | 3 | 3 | |

| S49-AC-2000 | Φ1920 | 2.9 | 1-3 | 3 | 3 |

Ultrasonic vibrating sieve change 220V, 50Hz or 110V, 60Hz electrical energy into 36KHz high-frequency electrical energy, then input ultrasonic transducer, it will become 36KHz mechanical vibration, the power of the ultrasonic wave make the screen with high-frequency vibration. When the materials vibration with low-frequency , superimposed on the ultrasonic vibration, screen mesh can prevent clogging, but also to improve the output and quality screening, to achieve the purpose of efficient screening and cleaning screen surface, ultra-fine powder is easy to sieve. The system introduces a low-amplitude and high-frequency ultrasonic vibration wave (mechanical wave) on the screen based on the traditional vibrating screen to improve the screening performance of the ultrafine particles. Particularly suitable for high value-added fine split users.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

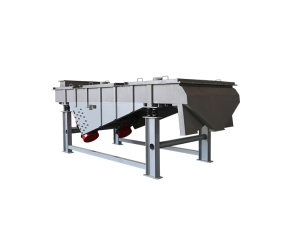

It has unique effects on the screening and classification of powdery and granular materials.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible