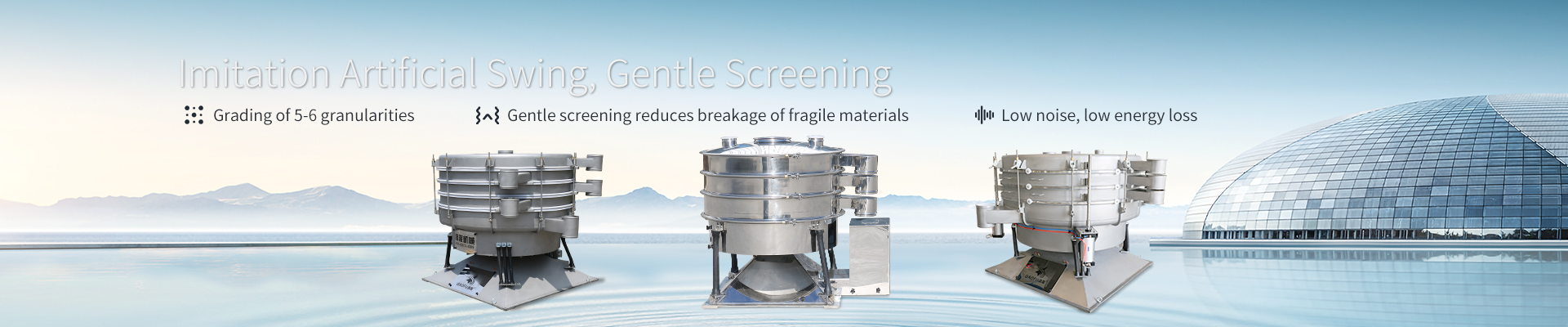

High capacity: Can achieve five-layer high-yield screening

High efficiency: Visible sieving efficiency and product yield

Low noise: Due to the simple modular design and low-speed operation, the noise is always ≤ 60~70Db, ensuring smooth and quiet operation;

Dust-proof operation: Do not require any auxiliary devices for air purification or dust collection other than the existing ventilation system on site. The system equip with airtight and vacuum designs, as well as chlorine purification, etc.

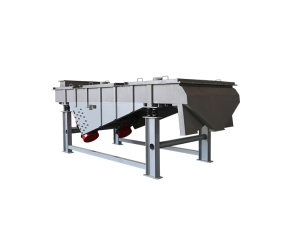

Citric acid, milk powder, starch, sugar, vitamins, spices, tea, feed, plastics, rubber, chemical fertilizers, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin, etc.

| Model | Dia.(mm) | Area(㎡) | Angle(°) | Layer(s) | Power (kW) |

| GFBD-600 | Φ600 | 0.21 | 0-10 | 1-5 | 0.75 |

| GFBD-1000 | Φ1000 | 0.66 | 0-10 | 1-5 | 1.1 |

| GFBD-1200 | Φ1200 | 0.98 | 0-10 | 1-5 | 2.2 |

| GFBD-1600 | Φ1600 | 1.81 | 0-10 | 1-5 | 4 |

| GFBD-2000 | Φ2000 | 2.8 | 0-10 | 1-5 | 5.5 |

| GFBD-2400 | Φ2400 | 4.15 | 0-10 | 1-5 | 5.5 |

| GFBD-2600 | Φ2600 | 5.31 | 0-10 | 1-5 | 5.5 |

| GFBD-3200 | Φ3200 | 7.5 | 0-10 | 1-5 | 11 |

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

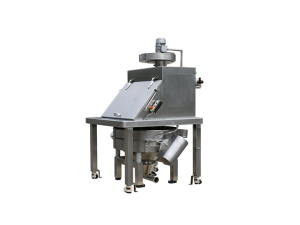

It has unique effects on the screening and classification of powdery and granular materials.

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible