Home / Products / Conveying and feeding / Tube Type Vibrating Feeder

Metallurgy, ceramics, abrasives, emery, non-metallic minerals, refractory materials, mining, food, chemicals, glass, building materials, etc.

Powdery, granular and small materials

Metallurgy, ceramics, abrasives, emery, non-metallic minerals, refractory materials, mining, food, chemicals, glass, building materials, etc.

Classification and particle size inspection of abrasives, superhard materials and other products

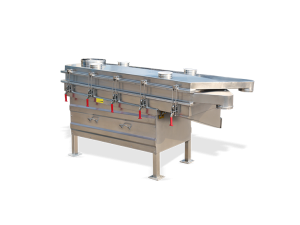

The basic working principle of the vibrating feeder is that after the equipment is started, two symmetrically arranged vibration motors or exciters of the same model and specifications run synchronously and in reverse direction, and the exciting force generated passes through the vibration transmission body – the motor or the exciter. The base of the exciter is transmitted to the entire vibrating body – the feed trough, causing the trough to vibrate periodically, so that the materials in the trough make a directional jumping movement toward the discharge end to complete the material conveying operation.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible