Home / Products / Fine Screening / Single Vibration Source Straight Sieve

Application:

Food industry, Pharmaceutical industry, Chemical industry

Material:

Flour, soy protein, milk powder, sugar, amino acids, food additives, condiments, yeast etc all powder materials screening.

Chinese medicine granules, Chinese medicine powder, pharmaceutical intermediates, Chinese Herbal Medicine, plant extracts, biological agents, etc.

Metals, metallurgy powder,etc.

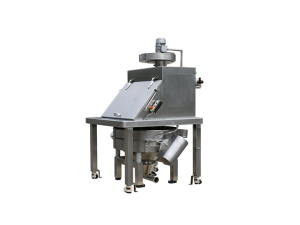

The straight sieve uses a high-frequency vibration motor as the excitation source. After the material enters the system, it undergoes a three-dimensional rotational movement on the screen surface due to the force of the vibration source. The flour and agglomerates are fully dispersed, and quickly pass through the screen and directly enter the lower noodle bin. Impurities and foreign matter are separated and discharged to the slag discharge port, playing the role of “quality assurance officer” on the production line.

The straight sieve can be used in the feeding system at the front end of production lines such as instant noodles, dried noodles, snacks, solid beverages, etc. to separate foreign matter in raw materials (flour, starch, milk powder, additives, etc.). Because it is connected in series in the system and automatically separates foreign matter, it is known as the “quality assurance officer” of the food production line. The flour sifter can replace the manual observation of finding foreign matter and sorting it.

Flour, soy protein, milk powder, sugar, amino acids, food additives, condiments, yeast etc all powder materials screening.

Chinese medicine granules, Chinese medicine powder, pharmaceutical intermediates, Chinese Herbal Medicine, plant extracts, biological agents, etc.

Metals, metallurgy powder,etc.

| Model | Power(KW) | Speed(r/min) | Dia.(mm) | Dimensions(mm) |

| DZ-600 | 0.18 | 1450 | Φ580 | 1000×600×550 |

| DZ-800 | 0.25 | 1450 | Φ780 | 1100×800×600 |

| DZ-1000 | 0.55 | 1450 | Φ960 | 1280×1000×700 |

| DZ-1200 | 0.75 | 1450 | Φ1160 | 1550×1200×750 |

| DZ-1500 | 1.5 | 1450 | Φ1460 | 1850×1500×900 |

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible