Home / Products / Conveying and feeding / LS Screw Conveyor

Building materials industry, metallurgical industry, chemical industry, electric power industry, coal and charcoal industry, machinery industry, light industry, grain industry and food industry, etc.

Sugar powder, starch, salt, soy milk, soy sauce, juice, tea, snacks, quick-frozen foods, condiments, protein, food additives, industrial drugs, traditional Chinese medicine powder, granular pills, pellets, resin, paint, aluminum powder, lead powder , copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials

Building materials industry, metallurgical industry, chemical industry, electric power industry, coal and charcoal industry, machinery industry, light industry, grain industry and food industry, etc.

Sugar powder, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, fruit juice, tea, brewed drinks, dairy products, candy, snacks, quick-frozen foods, condiments, protein, food additives, industrial drugs, traditional Chinese medicine powder, granules pills, pellets, resins, coatings, industrial drugs, cosmetics, paints, aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials , kaolin, lime, alumina, heavy calcium carbonate, quartz sand, waste oil, waste water, dyeing and finishing waste water, papermaking, additives, activated carbon, etc.

The LS screw conveyor uses a rotating screw to push the transported materials along a fixed casing to carry out transportation work. The head and tail bearings are moved outside the casing. The hanging bearing adopts a sliding bearing with a dust-proof sealing device.The bearing bush is generally made of powder metallurgy, the felt bearing bush is used for conveying cement, and the hanging shaft and the spiral shaft are connected by a slider.

Structural characteristics of LS screw conveyor: A screw conveyor usually consists of three parts: the main body, the inlet and outlet device, and the driving device. The body consists of three types: first section, middle section and last section. A thrust bearing is installed in the first section to bear the axial force, and a bearing is installed in the middle section and the tail section to support the screw shaft. In addition, a radial bearing that can move axially is installed in the tail section to compensate for the error in the length of the screw shaft. and adapting to changes in temperature. The screw shafts are connected by flanges to improve the interchangeability of the connecting shafts and facilitate maintenance.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

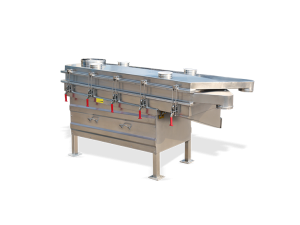

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible