Home / Products / Fine Screening / Rotary Vibrating Screen

Strong ability: Can sieve any powder down to 600 mesh(0.02mm), and filter mucus up to 5 microns;

High efficiency: 1 to 5 layers of sieves can be used to sort two to six particle size at the same time;

Brand name: “Xuanzhen”, which comes from the “Xuanzhen” trademark registered by Gaofu in 2000;

Many patents: Gaofu‘s innovation never stops. Only the rotating vibration decoration has successfully applied for 58 patents (see Tianyancha for details)

Battery materials, silicon materials, food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Lithium iron phosphate, ternary materials, graphite, polycrystalline silicon, monocrystalline silicon, sugar powder, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, juice, tea, brewed drinks, dairy products, candy, snacks, quick-frozen foods , condiments, proteins, food additives, industrial drugs, traditional Chinese medicine powder, granular pills, pellets, resins, coatings, cosmetics, paints, aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, Electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, waste oil, waste water, dyeing and finishing waste water, papermaking, additives, activated carbon, etc.

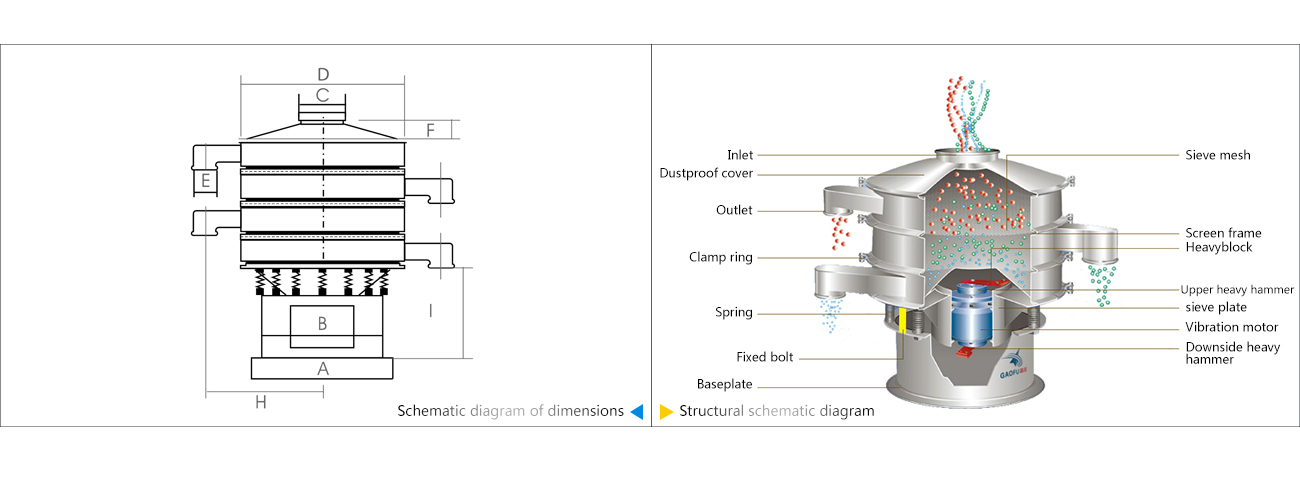

Rotary vibrating screen uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion, and then transfer this motion to screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Filter foreign matter

Rotary vibrating screen uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion, and then transfer this motion to screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Remove foreign matter

Rotary vibrating screen uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion, and then transfer this motion to screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

| Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | H (mm) | I (mm) | Single layer height(mm) | Double layers height(mm) | Three layers height(mm) |

| S49-600 | 530 | 430 | 246 | 600 | 100 | 70 | 391 | 415 | 785 | 910 | 1040 |

| S49-800 | 680 | 580 | 246 | 800 | 125 | 80 | 514 | 430 | 855 | 1005 | 1155 |

| S49-1000 | 800 | 700 | 246 | 1000 | 150 | 95 | 615 | 430 | 865 | 1015 | 1065 |

| S49-1200 | 975 | 855 | 400 | 1200 | 180 | 100 | 717 | 550 | 1020 | 1170 | 1320 |

| S49-1500 | 1190 | 1050 | 400 | 1500 | 180 | 116 | 866 | 545 | 1090 | 1270 | 1440 |

| S49-1800 | 1580 | 1440 | 400 | 1800 | 200 | 150 | 1070 | 675 | 1230 | 1400 | 1570 |

| S49-2000 | 1800 | 1640 | 400 | 2000 | 200 | 190 | 1210 | 685 | 1280 | 1445 | 1615 |

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

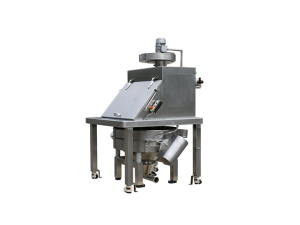

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

The small food flour supply system uses two flour or starch powder supply systems at the same time. It is mainly used for snack foods. The dough mixer automatically quantifies the dough during mixing. The quantification does not take up the dough mixing time, and a quantification cycle is completed in 3 minutes. , the blanking time is 10–20 seconds, and the quantification is accurate.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible