Home / Products / Related Equipment / Reaction Kettle Silo

Simple structure: Easy to clean, stable structure

Easy to use: Suitable for bulk materials with poor fluidity

High efficiency: Efficient handling of batches of bulk materials in automated production processes

Accuracy: Quantitatively and accurately distribute a variety of materials

Storage containers for powder and granular bulk materials in the food, pharmaceutical, chemical and metallurgical industries.

Suitable for chemical raw materials, toxic, harmful, poor fluidity materials, etc.

Suitable for chemical raw materials, toxic, harmful, poor fluidity materials, etc.

Replace the manual feeding of materials into the reactor directly. All electrical components, motors and other gas explosion-proof materials in this silo are rated BT4. The whole operation is closed and operated under nitrogen protection. Bridge breaking function inside the silo. The overall conveying and unloading process can be controlled intelligently by PLC or manually.

After the warehouse is filled by manual feeding, the closed nitrogen is replaced, and the bridge breaking device works while turning on the frequency converter to unload materials. The entire process of discharging materials into the reaction kettle is airtight, smooth, non-blocking and safe.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

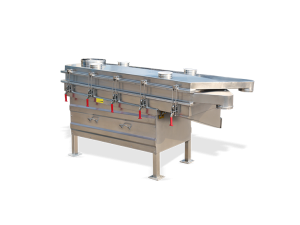

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible