It adopts the principle of plane gyration motion, which reduces the dynamic to static ratio and basic dynamic load of the equipment, improves the screening efficiency of qualified materials, and thus increases profits.

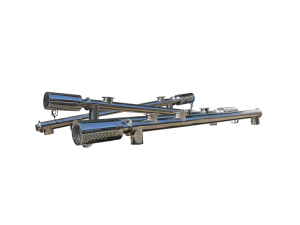

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

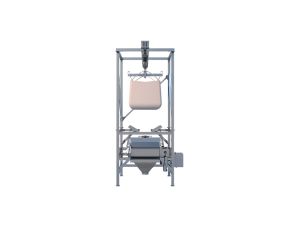

This equipment is suitable for unpacking and unloading dry powder and granular materials such as plastic resin and food additives in large bags in the fields of plastics, rubber, food, medicine, chemical industry, etc.

Due to the small circulation area in the body, the screw conveyor is not suitable for conveying materials that are perishable, too sticky, and easy to agglomerate.

Since the screen shafts are arranged according to different working angles, when the material runs at a higher working angle, the speed is faster; when the material runs at a lower working angle, the speed is slower. Materials running at two different speeds start to move axially when they meet at a certain position on the screen surface. The material layer can be evenly distributed on the screen surface, effectively improving screening efficiency.

GF4PG four teeth roller crusher is composed by teeth roller with high speed and strength to do the opposite running. The material free fall as meet the gap of teeth roller, the material bigger than two teeth roller gap will be instantly broken and free fall, to achieve the crushing purpose, meet the size requirements. Relative roller with differential operation can cleaning each slot of the material, so as to prevent sticking, blocking phenomenon and make the material without staying on the surface to avoid a repeat broken, avoid over – crushed.

The DZC vertical conveyor uses a vibration motor as the vibration source, and uses the combined amplitude of the two vibration motors to transport materials upward along the spiral conveyor trough. During the vibration process, when the motion acceleration in the direction perpendicular to the bottom of the trough is large enough, the material will break away from the bottom of the trough and fly in the air along a parabolic trajectory until it lands on the bottom of the trough again, thus completing a movement process; the cycle starts again and again, so that the material moves along the spiral groove. Move upward to complete the conveying process. DZC vertical conveyor is mainly used to lift granular, powdery and block materials. This conveyor has a simple structure and is easy to maintain. It can deliver materials in a quantitative manner and the conveying volume is continuously adjustable. It can be used for vertical transportation of small and medium-sized particles in various industries. In addition to lifting materials from bottom to top, it can also complete drying and cooling of materials. effect. It has two structures: trough type and closed type. According to the requirements of different processes, we can design a screening elevator for material particle classification and an elevator for flammable and explosive materials.

The feeding process of the electromagnetic vibrating feeder is realized by using the electromagnetic vibrator to drive the feeding trough to reciprocate periodically in the inclined direction. When the vertical component of the acceleration of the feeder vibration is greater than the acceleration of gravity, the materials in the trough will be thrown up. , and jump forward according to the trajectory of the parabola. The throwing and falling are completed within 1/5 second. Every time the material trough vibrates, the material in the trough is thrown up and jumps forward. In this way, the trough body moves at a rate of 3,000 times per minute. Frequency vibration causes the material to be thrown up and jump forward accordingly, making the material move forward evenly and continuously to achieve feeding.