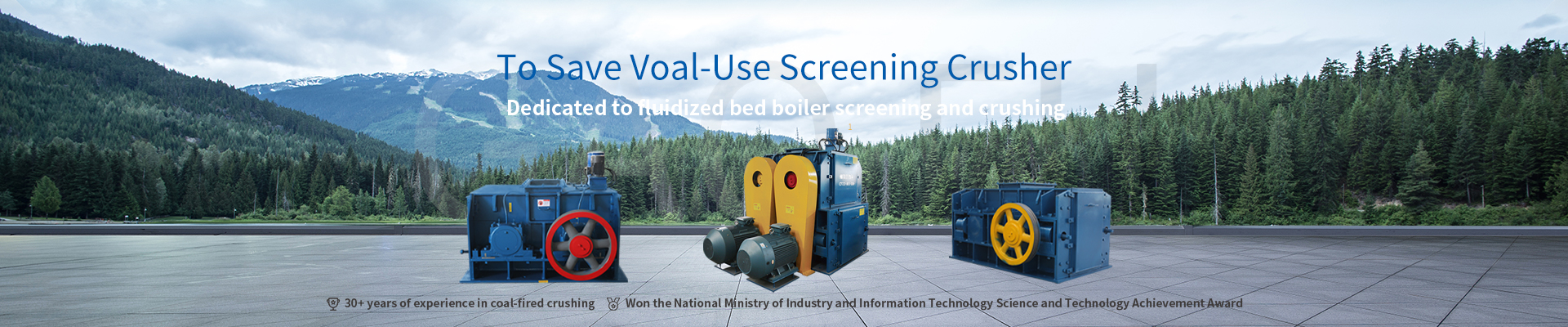

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

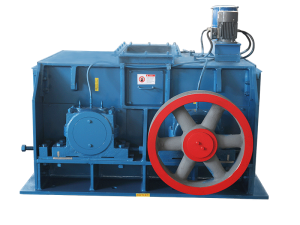

The banana-shaped vibrating screen is a self-synchronizing heavy-duty equal-thickness screen. The screen box is similar to the shape of a banana. The screen beam adopts a box-shaped beam. The vibrating screen transmission system consists of a motor passing through a pulley and a V-belt, and then a universal connecting shaft transmits the energy to the vibration screen. The vibrator and the exciter are connected by an intermediate transmission shaft. The screen surface adopts the form of fold lines with different inclination angles, and the thickness of the material layer does not change from the inlet end to the outlet end. The material volume and flow rate ratio on each section of the screen surface is stable, the material layer is high, and the material is in a uniform state. The screening efficiency is significantly improved, and the processing capacity is 1-2 times higher than that of the vibrating screen with the same effective area. For materials with high fine particle content, especially When the content of materials whose medium content accounts for less than 1/2 of the classified particle size is large, the banana-type vibrating screener has higher screening efficiency.

When BTS bar screen work, the exciting force generated by the vibration exciter through the screen box to pass through to the screen surface, because the exciter vibration force generated by the longitudinal force, fForcing the sieve box to drive the sieve surface to make longitudinal before and after displacement. Under certain conditions, the material on the screen surface is thrown forward due to the exciting force, and the material smaller than the screen hole will fall down through the screen to the lower layer. The BTS bar vibrating screen material’s movement on the screen surface is parabolic, and the bar vibrating screen performs the material screening operation due to such repeated movement of the material.

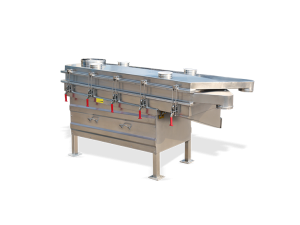

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo.

The solid-liquid separation centrifugal screen can handle oversized solid particles in the form of plant fibers, intercept and recycle purified resin particles, and intercept mixture agglomerations, etc.

It is widely used in scientific research, production and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments to screen and test materials.

High screening accuracy and accurate detection results. Suitable for particle shape, particle size distribution and various detection