Home / Products / Fine Screening / Filtration Sieve Machine

High efficiency: High screening and filtration efficiency, can be sieved to 400 mesh

Save time: Easy to change the screen, simply operate and easily clean

Automation: Impurities and coarse materials are automatically discharged, enabling automated operations

Easy to operate: Small size, light weight, can make full use of space, easy to move.

Food industry, Chemical industry, Pharmaceutical industry, Ceramic abrasive, Metallurgy industry, etc.

Food industry, Chemical industry, Pharmaceutical industry, Ceramic abrasive, Metallurgy industry, etc.

Flour, milk powder, starch, fish meal, rice noodles, condiments, beverages, fruit juices, sugar, soy sauce, yeast, paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder, Chinese medicine powder, Chinese medicine, Western medicine powder, aluminum paste, mud, kaolin, quartz sand, alumina, artificial black aluminum, graphite, silicon carbide, spray soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

| Name | Unit | Value | ||

| Sieve frame | s | 1 | 1 | |

| Diameter | mm | Φ450 | Φ550 | |

| Input size | mm | 0.038-5 | 0.038-5 | |

| Noise | dB | ≤85 | ≤85 | |

| Amplitude | mm | ≤5 | ≤5 | |

| Motor | Voltage | V | 380 | 380 |

| Speed | r.p.m | 1450 | 1450 | |

| Powder | kW | 0.18 | 0.25 | |

Filter screen is also called filter screening machine. This equipment uses vibration motor as the excitation source.It is a small vibrating screening equipment with high screening, low noise and small volume designed to facilitate moving working surface. The filter vibrating screening machine (filter screen) is suitable for single-layer screening and filtration by manufacturers in various industries. It handles materials with low production volume or low impurities,widely used in food, medicine, chemical industry, metallurgy, abrasives, ceramics, coatings, diamond, mining and other industries.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

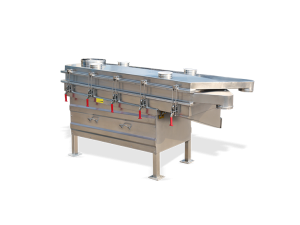

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible