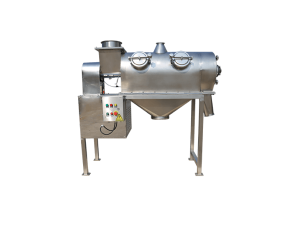

Home / Products / Explosion-proof equipment / Explosion-Proof Vibrating Screen

Product introduction:

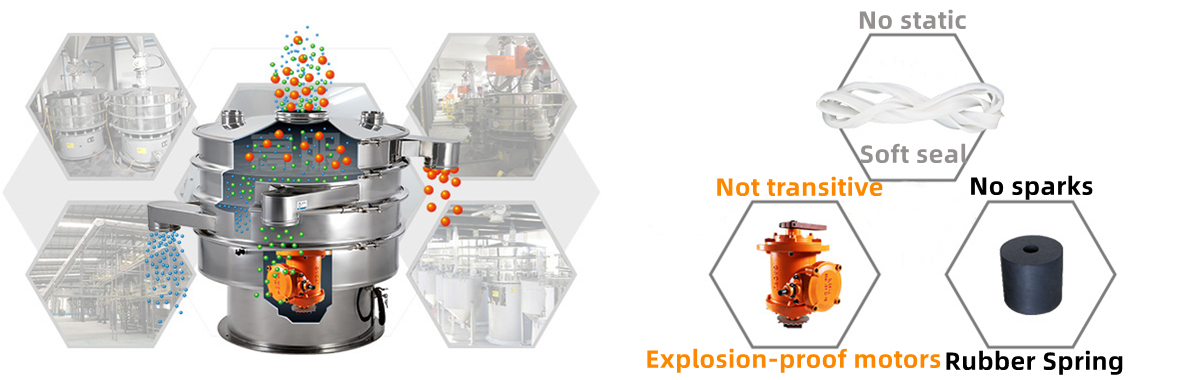

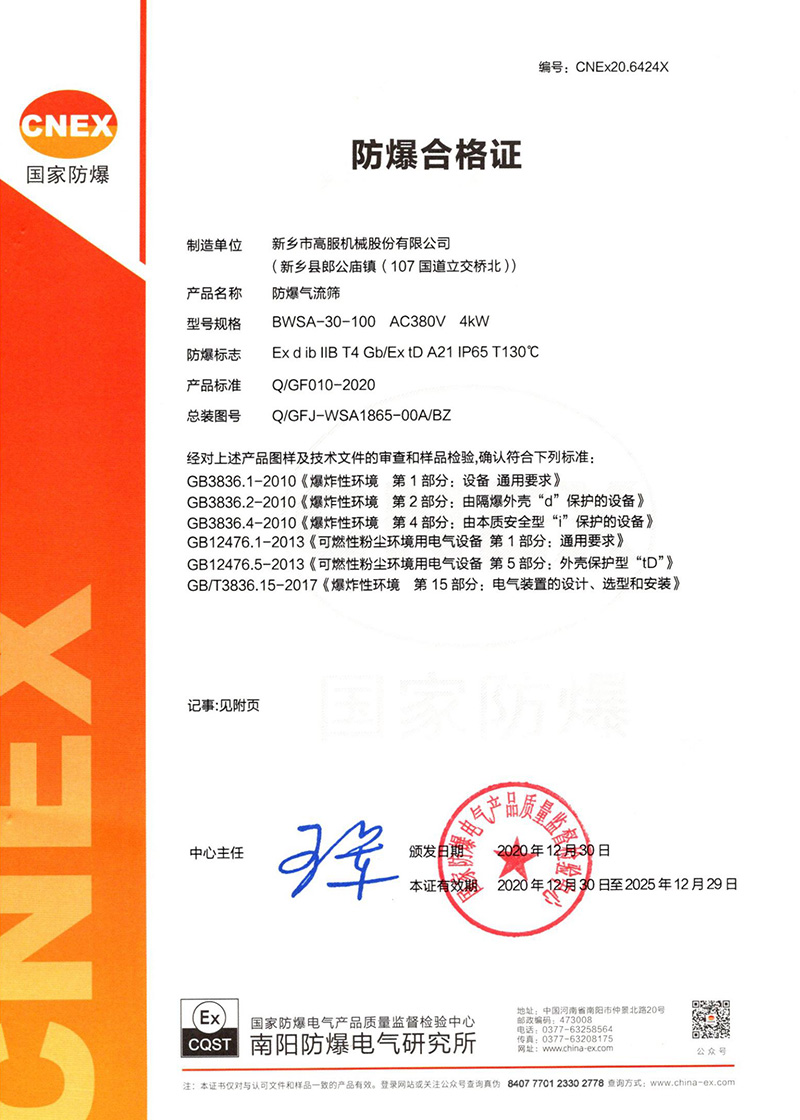

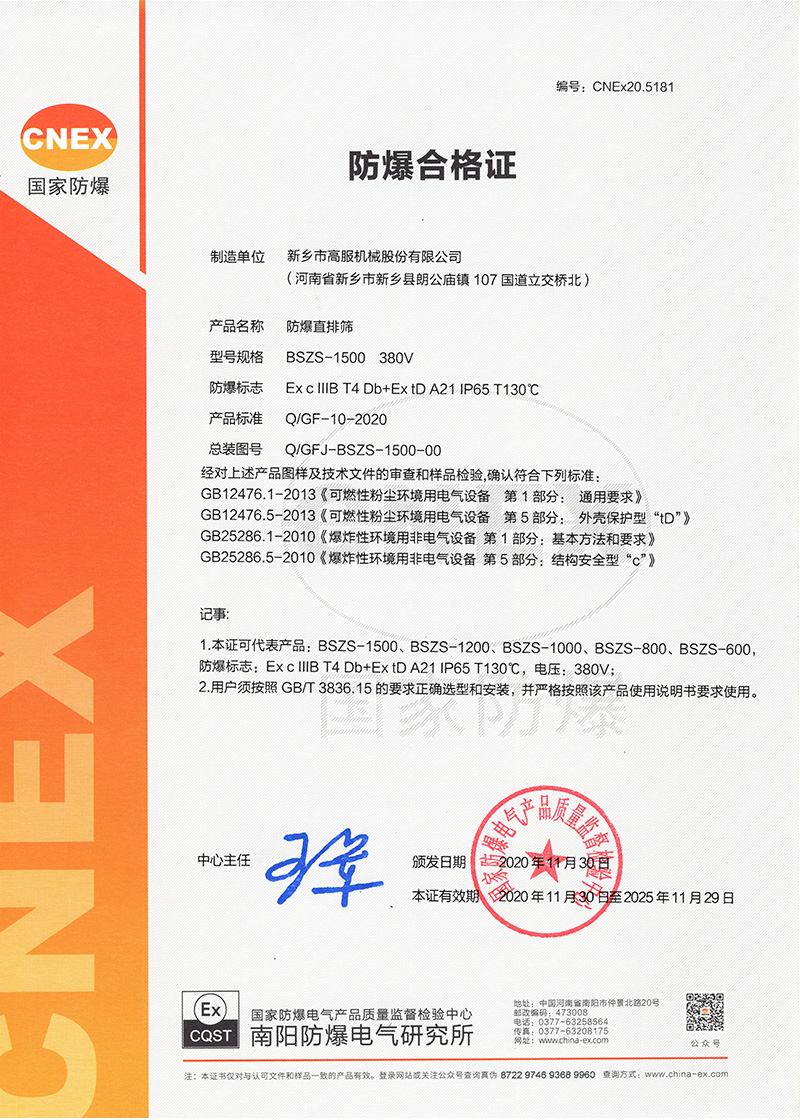

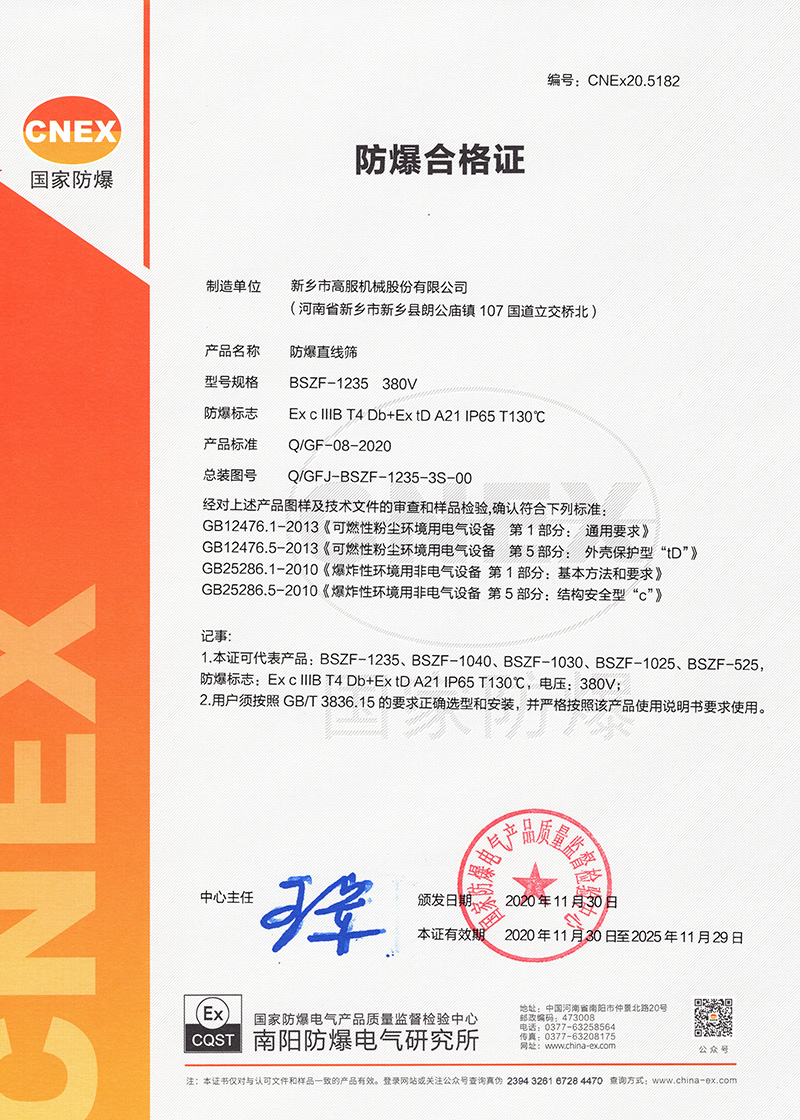

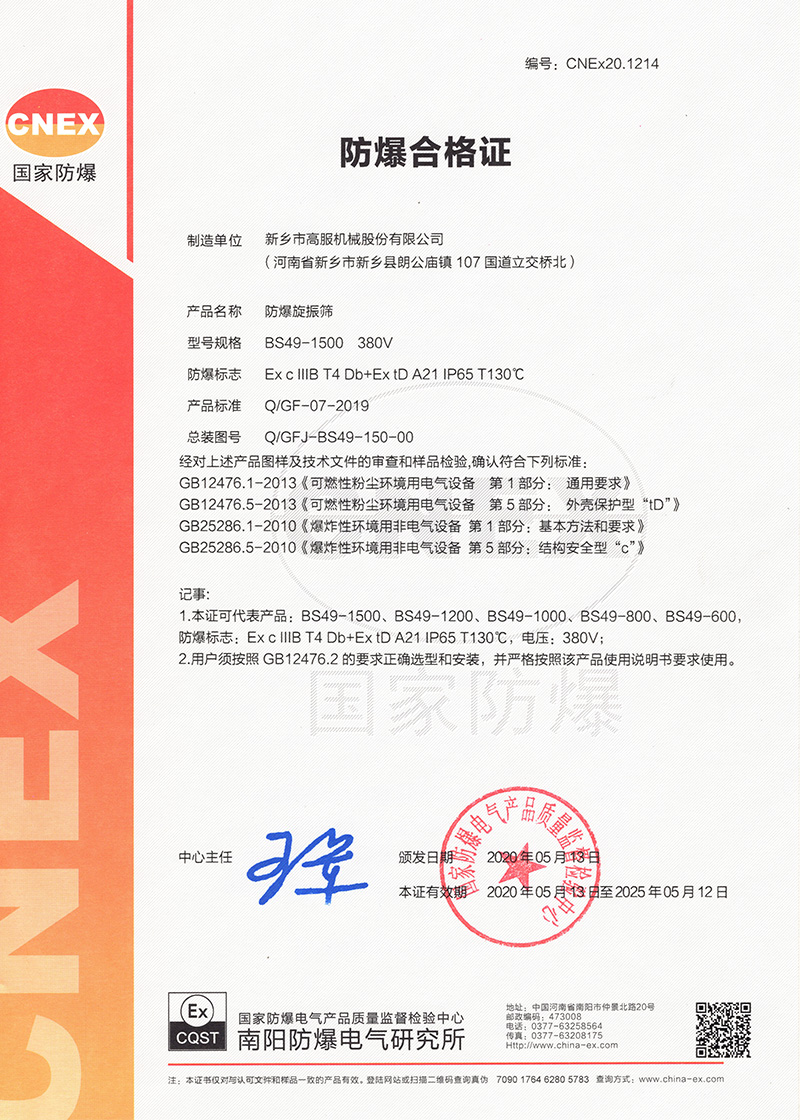

The explosion-proof vibrating screen is suitable for screening flammable and explosive materials. The explosion-proof mark is Ex d IIB T4 Gb/Ex tD A21 IP65 T130℃. It is suitable for the food industry, pharmaceutical industry, chemical industry, metal powder industry, lithium battery industry and other industries.

What are the hidden dangers in screening operations?

1. Dust accumulation—poor sealing performance of the equipment leads to material leakage and flying in the air;

2. Impact friction, electrostatic discharge – friction between equipment generates static electricity;

3. Electrical sparks and high-temperature objects—sparks are generated when the motor is started.

Food industry, pharmaceutical industry, chemical industry, metal powder industry, lithium battery industry

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

The materials are always under positive pressure during the screening process. The materials to be screened and a large amount of dust are pressed into the screen body through the feed port and enter the mesh cage. The finished products quickly pass through the mesh under the action of positive pressure. The remaining gas is dissipated through the bag dust collector and suction device of the silo. 10mg/m³, solves the problem of dust flying

When two vibrating motors installed longitudinally on the screen body run relative to each other, the horizontal excitation forces generated by them cancel each other out due to the relative operation of the motors, and the longitudinal excitation force is transmitted to the entire screen box through the vibration transmission body. The screen surface is vibrated, so that the materials on the screen surface are subject to the excitation force and jump on the screen surface in the direction of the discharged product. The materials smaller than the screen hole fall to the lower layer through the screen hole, and then jump from The discharge port flows out. Due to the reasonable screening process, after the materials are classified by the vibrating screen, several materials with different particle sizes can be obtained to complete the material classification operation.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible