Home / Products / Explosion-proof equipment / Explosion-proof straight Sieve

Strong ability: tight sealing, no liquid leakage, no dust flying

High efficiency: Can be connected in series to the production line system, with low energy consumption and 24-hour continuous production

Easy to clean: Easy to clean inside and outside, no sanitary dead corners, in line with the standards for use in the food and pharmaceutical industries

Easy to operate: The unique structure and mesh frame design improves the durability of the screen, makes screen replacement within 5 minutes, and is easy to disassemble and assemble

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Flour, starch, milk powder, additives, carbon black (white carbon black), quartz powder (sand), mica, fluorescent powder, feldspar powder, kaolin, silica black soil, fly ash, glass beads, environmental protection, plastics, magnetic materials, building materials, mining, kiln industry, feed, condiments, fish meal, rice flour, flour, soybean meal, milk powder, egg powder, starch, sugar, fruit juice, Western medicine powder, Chinese medicine powder, pharmaceutical intermediates, pearls powder, soda ash, polyethylene, resin powder (PVC, epoxy), washing powder, auxiliaries, paint, dyes, pigments, rubber, coatings, alloy powder, gold powder, silver powder, copper powder, aluminum powder, nickel powder, chromium powder, magnesium powder, zinc powder, barium powder, vanadium powder, titanium powder, strontium powder, lead powder, foundry sand, etc.

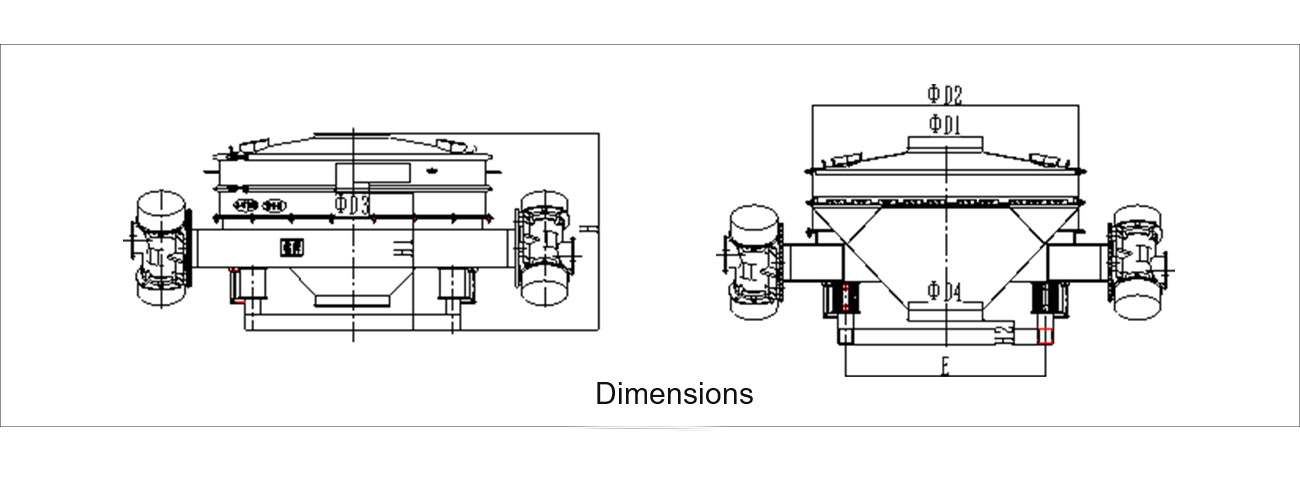

| Model | φD1(mm) | φD2(mm) | φD3(mm) | φD4(mm) | R(mm) | H(mm) | H1(mm) | H2(mm) | E(mm) | Anchor hole(mm) |

| BSZS-600 | 246 | 560 | 100 | 200 | 427 | 528 | 327 | 143 | 337*337 | 4-φ12.5 |

| BSZS-800 | 246 | 760 | 150 | 300 | 560 | 584 | 338 | 111 | 454*454 | 4-φ12.5 |

| BSZS-1000 | 246 | 930 | 150 | 350 | 645 | 652 | 397 | 54 | 587.5*587.5 | 4-φ12.5 |

| BSZS-1200 | 400 | 1130 | 180 | 400 | 747 | 852 | 571 | 158 | 700*700 | 4-φ12.5 |

| BSZS-1500 | 400 | 1430 | 180 | 400 | 900 | 1016 | 710 | 120 | 1080*700 | 4-φ12.5 |

Technical Parameters

| Model | Screening area(m2) | Diameter(mm) | Motor | Motor synchronous speed(r.p.m) | Power(kW) | Motor explosion-proof mark |

| BSZS-600 | 0.23 | φ560 | YBZ-1005-B | 1500 | 0.25 | Ex d IIB T4 Gb or Ex tb ⅢC T130° Db |

| BSZS-800 | 0.42 | φ760 | YBZ-1005-B | 0.25 | ||

| BSZS-1000 | 0.64 | φ930 | YBZ-1005-4 | 0.25 | ||

| BSZS-1200 | 0.95 | φ1130 | YBZ-1210-4 | 0.55 | ||

| BSZS-1500 | 1.61 | φ1430 | YBZ-1420-4 | 1.1 |

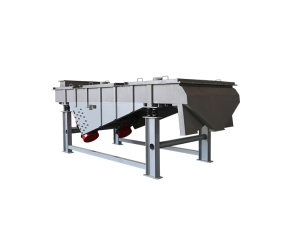

The explosion-proof straight sieve adopts high-frequency vibration motor as the excitation source. After the material enters the system, it undergoes a three-dimensional rotational movement on the screen surface due to the force of the vibration source. The flour and agglomeration fully dispersed, rapid through mesh directly to the lower silo. Foreign matter and impurities are separated and discharged to the slag discharge port, the machine play the role of “safety officer” on the production line.

It adopts advanced sealing technology to prevent leakage and extend service life. The sealing gap can be automatically compensated with the use process.

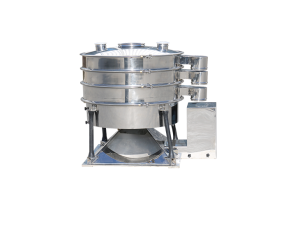

It has unique effects on the screening and classification of powdery and granular materials.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible