Home / Products / Conveying and feeding / Electromagnetic Vibrating Feeder

Application scope: Food industry, pharmaceutical industry, chemical industry, abrasive industry, non-metal industry, other industries, etc.

Application materials: Rock sugar, potato chips, cocoa beans, tablets, pharmaceutical powder, pharmaceutical granules, quartz sand, zirconium corundum, silicon carbide, plastic granules, rubber powder, PVC granules, etc.

Food industry, pharmaceutical industry, chemical industry, abrasive industry, non-metal industry, other industries, etc.

Rock sugar, potato chips, cocoa beans, tablets, pharmaceutical powder, pharmaceutical granules, quartz sand, zirconium corundum, silicon carbide, plastic granules, rubber powder, PVC granules, etc.

The feeding process of the electromagnetic vibrating feeder is realized by using the electromagnetic vibrator to drive the feeding trough to reciprocate periodically in the inclined direction. When the vertical component of the acceleration of the feeder vibration is greater than the acceleration of gravity, the materials in the trough will be thrown up. , and jump forward according to the trajectory of the parabola. The throwing and falling are completed within 1/5 second. Every time the material trough vibrates, the material in the trough is thrown up and jumps forward. In this way, the trough body moves at a rate of 3,000 times per minute. Frequency vibration causes the material to be thrown up and jump forward accordingly, making the material move forward evenly and continuously to achieve feeding.

The electromagnetic vibrating feeder is a relatively complete elastic system with dual mass points directional forced vibration. The entire system works in a low critical resonance state. It mainly uses an electromagnetic exciter to drive the trough to vibrate reciprocally at a certain inclination angle to move the material along the trough. . The material is placed on the feed tank supported by the main vibration spring. The armature is integrated with the main vibration spring of the tank, and the coil is wound around the iron core. Since the half-wave rectified unidirectional pulsating current flows through the coil, the electromagnet generates corresponding pulse electromagnetic force. In the positive half cycle of the alternating current, the pulsating current flows through the coil, generating a pulsating electromagnetic attraction between the iron core and the armature, causing the tank to move backward, and the main spring of the exciter deforms to store potential energy; in the negative half cycle, There is no current passing through the coil, the electromagnetic force disappears, and the armature separates from the electromagnet under the action of the spring force, causing the material trough to move forward, so that the material trough continuously vibrates back and forth at the frequency of the AC power supply.

Bucket elevator is a continuous conveying machine that uses a series of hoppers evenly fixed on the traction component to vertically lift materials. It is divided into three types: ring chain, plate chain and belt. It can adjust the transmission volume according to the transmission speed, and can choose the lifting height as needed. The hopper is designed and manufactured by our company. Wear-resistant, corrosion-resistant and other materials can be selected according to the on-site working conditions.

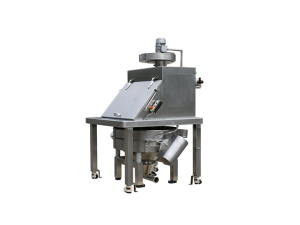

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

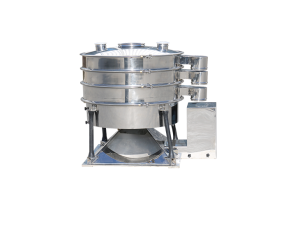

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible