Home / Products / Conveying and feeding / Electromagnetic Vibrating Feeder

Metallurgy, ceramics, abrasives, emery, non-metallic minerals, refractory materials, mining, food, chemicals, glass, building materials, etc.

Classification and particle size inspection of abrasives, superhard materials and other products

Metallurgy, ceramics, abrasives, emery, non-metallic minerals, refractory materials, mining, food, chemicals, glass, building materials, etc.

Classification and particle size inspection of abrasives, superhard materials and other products

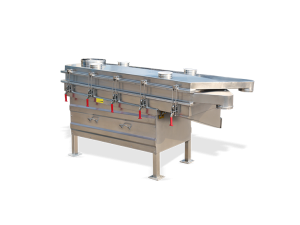

Electromagnetic vibrating feeder is a relatively complete elastic system with dual mass point forced vibration. The whole system works in the low critical resonance state. The electromagnetic vibrator drives the trough to make reciprocating vibration with a certain inclination to move the materials along the trough . The material is placed on the feed tank body supported by the main vibration spring, and the armature is connected with the main vibration spring of the tank body, and the coil is wound on the iron core. As the coil is flowing through the half-wave rectified unidirectional ripple current, therefore, the electromagnetic pulse generated on the corresponding electromagnetic force. In the positive half cycle of the alternating current, the pulsating current flows through the coil, a pulsating electromagnetic force is generated between the iron core and the armature, so that the tank body moves backward. The main spring of the vibration exciter deforms and stores the potential energy. During the negative half cycle, No current through the coil, the electromagnetic force disappears, the armature in the spring force separated from the electromagnet, the trough forward movement, so trough on the AC power frequency, continuous reciprocating vibration.

Using airflow to atomize raw materials into monomers can solve problems such as black spot removal, stickiness, agglomeration, dust, and pollution, which can improve product purity and improve product quality.

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible