High output: 5-10 times than other lkind of vibrating screen;

High efficiency: Screening efficiency is up to 95%;

Used in combination: Can be used in conjunction with various grinding machines and wind types;

Cost savings: Low noise, low energy consumption, continuous operation, and reduced maintenance.

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Various powders, etc.

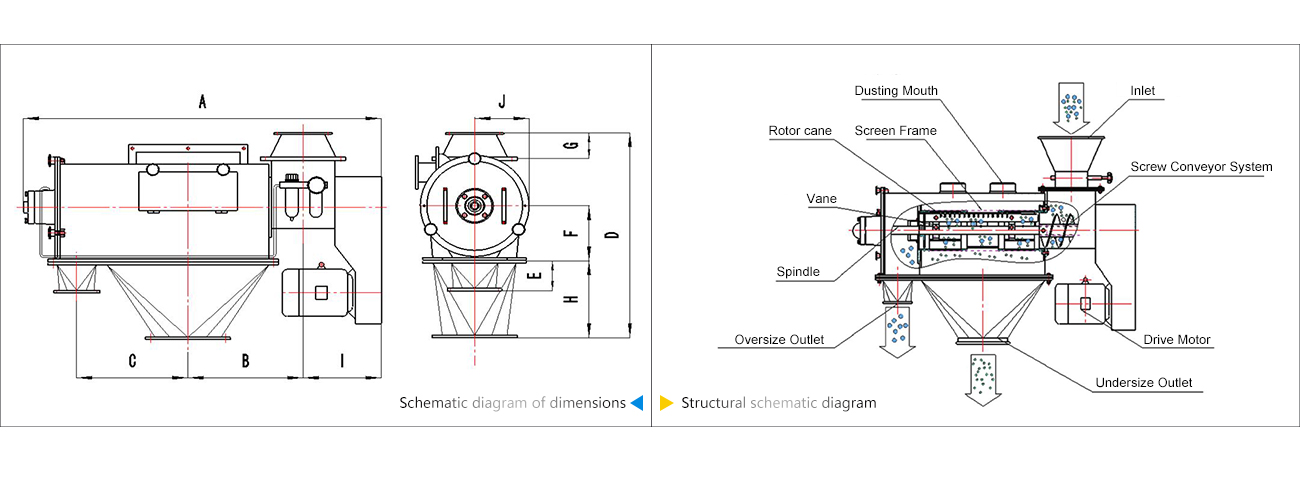

| Model | Capacity(kg/h) | Processing accuracy(%) | Screen mesh | Cage diameter(mm) | Cage length(mm) | Network surface area(m²) | Gap between blade and screen(mm) | Spindle speed(r/min) | Power(kW) |

| QLSP18-65 | 3000 | ≥85 | 5~500 | 180 | 650 | 0.36 | 3~10 | 815~1110 | 2.2 |

| QLSP30-100 | 5000 | 300 | 1000 | 0.94 | 820~980 | 4 | |||

| QLSX30-80 | 5000 | 300 | 800 | 0.75 | 820~980 | 4 | |||

| QLSS20-65 | 3500 | 200 | 650 | 0.4 | 1450 | 2.2 | |||

| QLSZ20-65 | 3500 | 200 | 650 | 0.4 | 1450 | 2.2 | |||

| QLSZ40-90 | 5000 | 400 | 900 | 1.1 | 960 | 5.5 | |||

| QLSL20-60 | 30m³/h | 200 | 600 | 0.37 | 5~10 | 960 | 1.5 |

Note 1: The processing capacity takes flour as an example, and the screening mesh is 30 mesh.

Note 2: The substances processed by QLSL200-600 take traditional Chinese medicine preparations as an example, and the screening mesh size is 30 mesh.

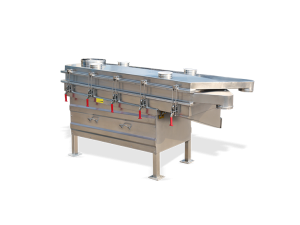

A quick-release linear vibrating screen designed and manufactured to meet the high-end requirements of food, pharmaceutical and other industries.

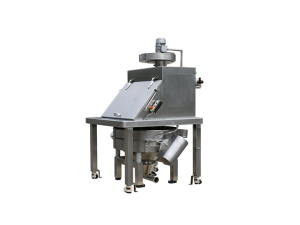

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

Impurities and foreign matter are separated and discharged to the slag discharge port. The safety officer of the production line

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible