Home / Products / System equipment / Metallurgical Powder Systems / 3D printing material screening system

Material:3D printing materials industry

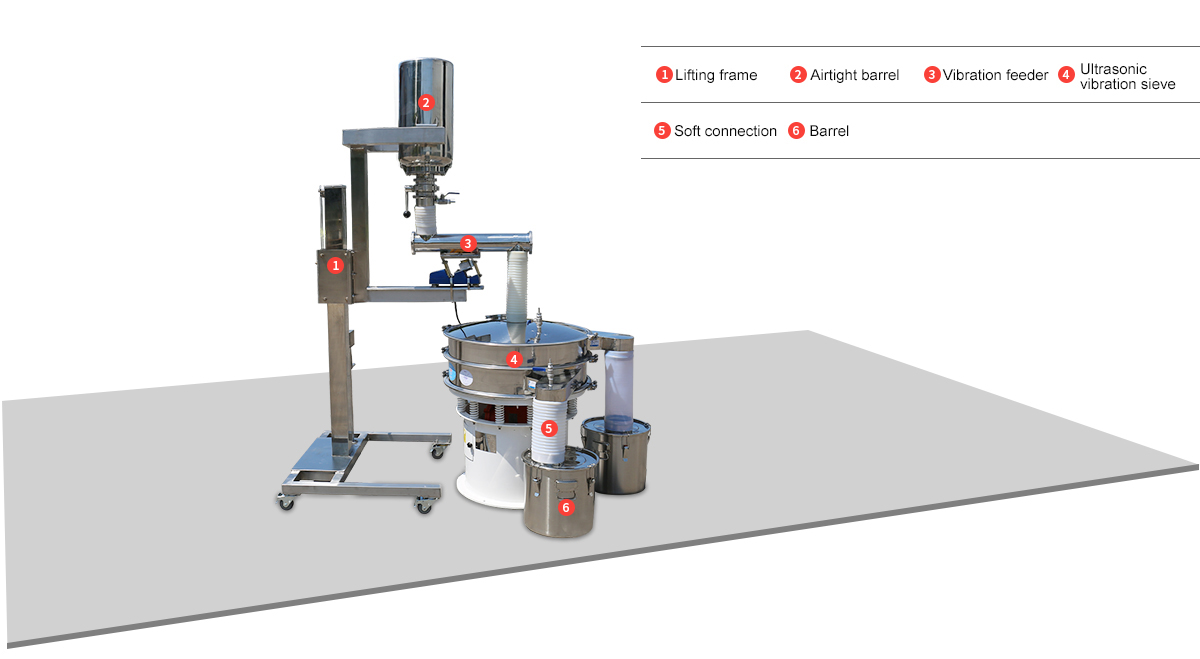

The 3D printing material powder is put into the airtight material bucket in advance. The valve below the material bucket can control the passing speed of the powder.

The powder enters the vibrating feeder below, and the vibrating feeder uniformly transports the material to the ultrasonic vibrating screen through vibration. The ultrasonic vibrating screen generates three-dimensional motion through the vibrating motor, which forces the material to jump and roll on a certain track on the screen.

The ultrasonic anti-clogging system can disperse the electrostatic clumping and sticky powder, accelerate the efficiency of the screen, and the smaller powder fall through the screen, discharge from the lower discharge port, and enter the air-tight buffer barrel through the soft silica coupling for standby.

The larger powder moves in a certain trajectory on the screen and is discharged from the upper discharge port. Connect into the airtight buffer barrel to complete the screening operation. Considering that some 3D printing materials need to be protected by inert gas during the screening process, the equipment has reserved air inlets and exhaust ports.

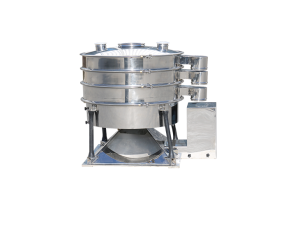

Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

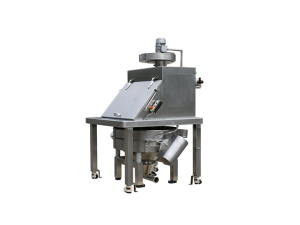

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

It can screen 6 particle sizes, and the sieve body diameter ranges from 600mm (24 inches) to 2600mm (104 inches)

Please fill in your phone number, email and other information, which will help us contact you in time and solve your problems as soon as possible