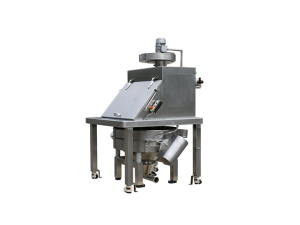

This equipment is suitable for unpacking, placing, screening and unloading small bags of materials in the food, pharmaceutical, chemical and metallurgical industries.

It is suitable for many industries such as medicine, foodstuff, chemical industry, metallurgy and building material, aiming at the confinement transportation of various powder materials, improving the cleanliness of materials, which can meet the diversified transportation needs of different customers.

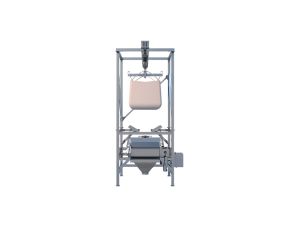

This equipment is suitable for unpacking and unloading dry powder and granular materials such as plastic resin and food additives in large bags in the fields of plastics, rubber, food, medicine, chemical industry, etc.

Due to the small circulation area in the body, the screw conveyor is not suitable for conveying materials that are perishable, too sticky, and easy to agglomerate.

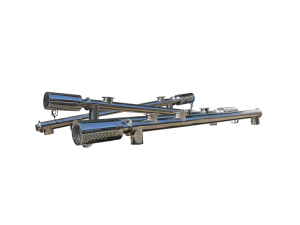

The DZC vertical conveyor uses a vibration motor as the vibration source, and uses the combined amplitude of the two vibration motors to transport materials upward along the spiral conveyor trough. During the vibration process, when the motion acceleration in the direction perpendicular to the bottom of the trough is large enough, the material will break away from the bottom of the trough and fly in the air along a parabolic trajectory until it lands on the bottom of the trough again, thus completing a movement process; the cycle starts again and again, so that the material moves along the spiral groove. Move upward to complete the conveying process. DZC vertical conveyor is mainly used to lift granular, powdery and block materials. This conveyor has a simple structure and is easy to maintain. It can deliver materials in a quantitative manner and the conveying volume is continuously adjustable. It can be used for vertical transportation of small and medium-sized particles in various industries. In addition to lifting materials from bottom to top, it can also complete drying and cooling of materials. effect. It has two structures: trough type and closed type. According to the requirements of different processes, we can design a screening elevator for material particle classification and an elevator for flammable and explosive materials.

The feeding process of the electromagnetic vibrating feeder is realized by using the electromagnetic vibrator to drive the feeding trough to reciprocate periodically in the inclined direction. When the vertical component of the acceleration of the feeder vibration is greater than the acceleration of gravity, the materials in the trough will be thrown up. , and jump forward according to the trajectory of the parabola. The throwing and falling are completed within 1/5 second. Every time the material trough vibrates, the material in the trough is thrown up and jumps forward. In this way, the trough body moves at a rate of 3,000 times per minute. Frequency vibration causes the material to be thrown up and jump forward accordingly, making the material move forward evenly and continuously to achieve feeding.

Bucket elevator is a continuous conveying machine that uses a series of hoppers evenly fixed on the traction component to vertically lift materials. It is divided into three types: ring chain, plate chain and belt. It can adjust the transmission volume according to the transmission speed, and can choose the lifting height as needed. The hopper is designed and manufactured by our company. Wear-resistant, corrosion-resistant and other materials can be selected according to the on-site working conditions.

The ZG series motor vibrating feeder is a general-purpose feeding equipment that is becoming increasingly standardized. It is widely used in related industries to transport various lumpy and granular powdery materials over short distances. This machine can work well with continuous conveying equipment such as belt conveyors, automatic weighing and quantitative packaging systems to achieve online and automated operations. It is an ideal feeder for metallurgy, mining, coal, building materials, chemical industry, electric power and food processing industries. materials and conveying equipment.

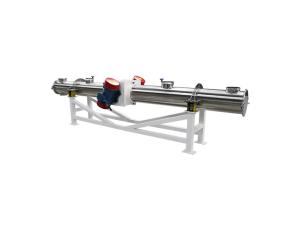

The tubular vibrating feeder is a linear vibrating inertial conveyor. The width and depth of the trough determine its processing capacity, and the effective length of the trough determines its conveying distance. It has the characteristics of simple and compact structure, uniform and continuous feeding, and easy maintenance.