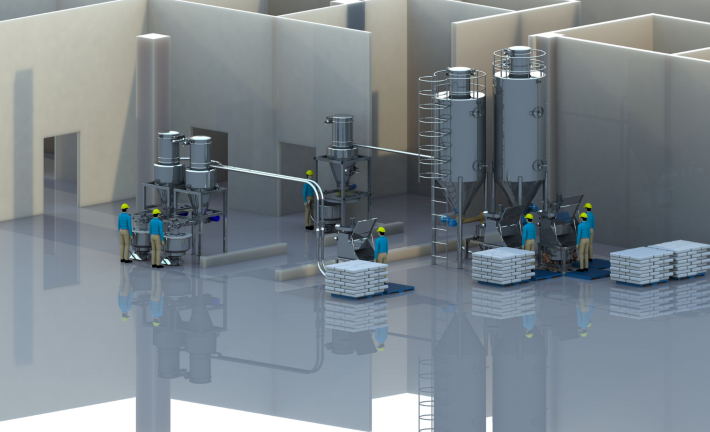

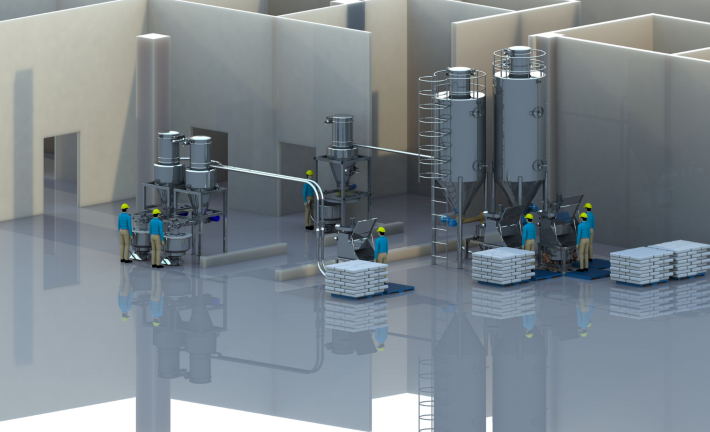

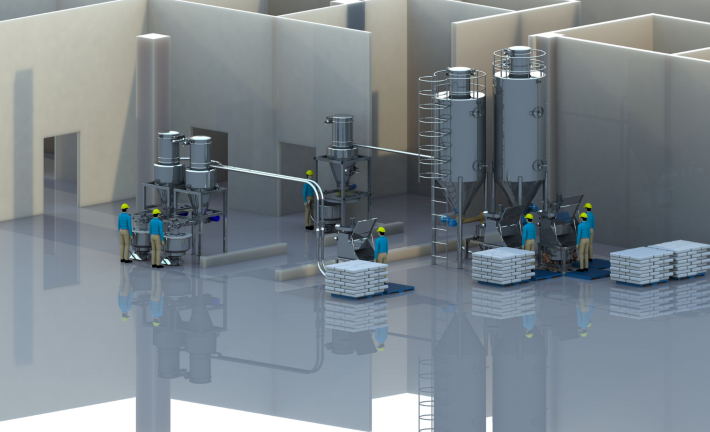

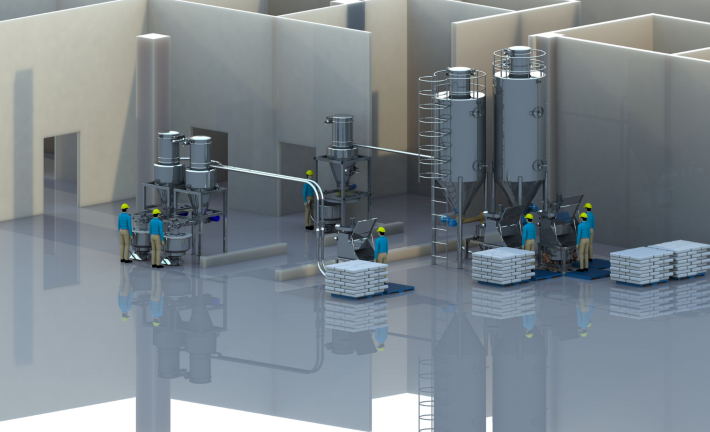

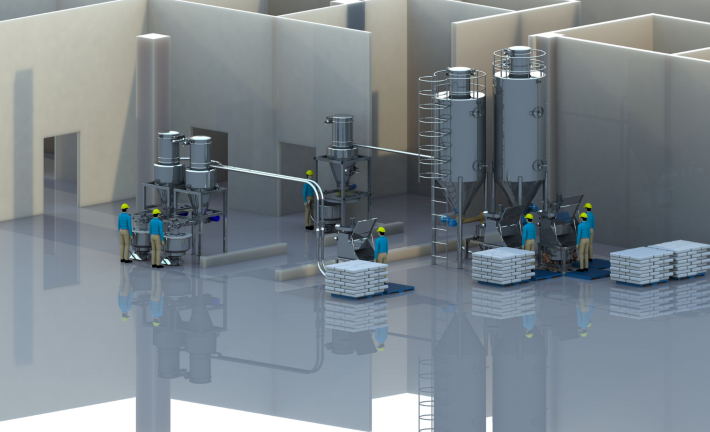

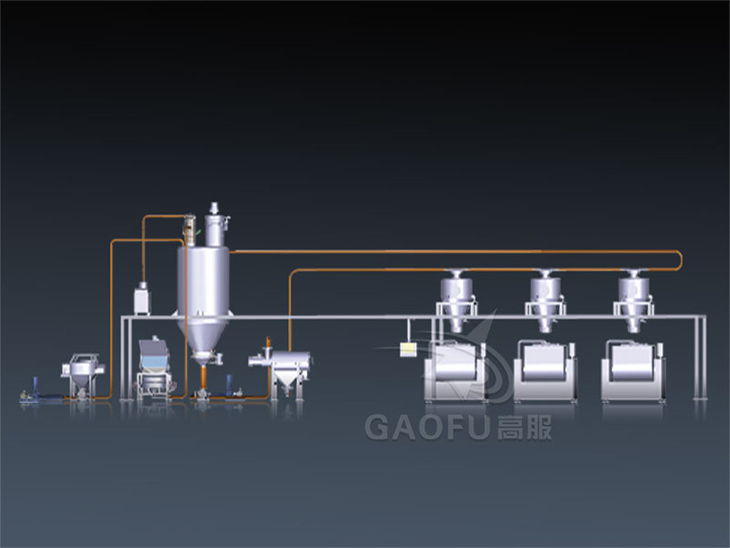

dust-free feeding system, online screening, “zero” burden on workers

The quality inspector in the production system, equivalent to the “kidney” of the human body, helping you keep out unqualified materials.

Mining vibrating screen can be divided into: probability screens, high-efficiency heavy-duty screens, YK circular vibrating screen, dewatering screens, banana screens, linear vibrating screen, etc.

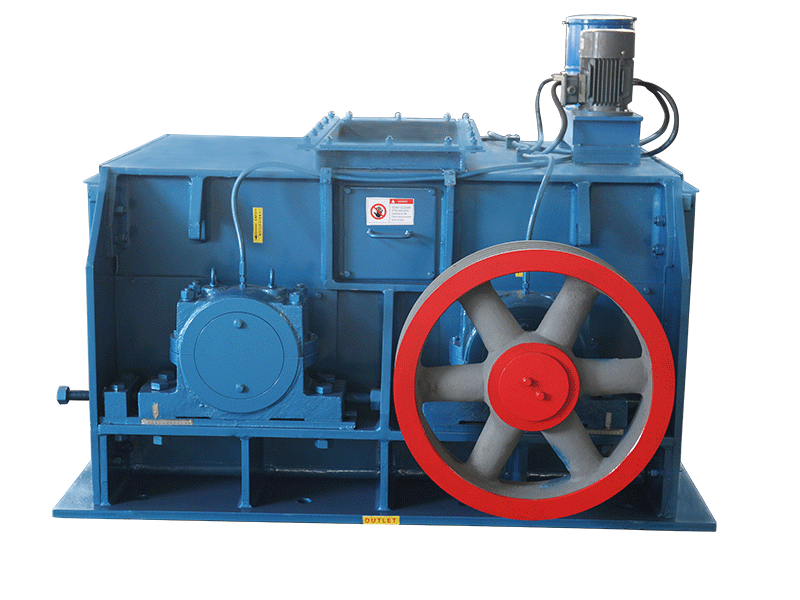

Committed to fluidized bed boiler coal crushing

dust-free feeding, negative pressure conveying, quantitative feeding, dust-free, environmentally friendly and safe

Gaofu, around the world, innovation never stops

Customizable to meet your industry's unique needs and industry standards

Systematic solution dedicated to raw material receiving, online screening, and multi-point feeding.

Suitable for food processing enterprises that need automated production and truly solve environmental protection and safety issues.

The rotary vibrating screen uses a vertical vibrating motor as the excitation source. The upper and lower ends of the vibrating motor are equipped with eccentric weights, which convert the rotating motion of the vibrating motor into horizontal, vertical, and tilted three-dimensional movements. This movement is transmitted to the screen surface.

food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

Ultrasonic vibrating sieve change 220V, 50Hz or 110V, 60Hz electrical energy into 36KHz high-frequency electrical energy, then input ultrasonic transducer, it will become 36KHz mechanical vibration, the power of the ultrasonic wave make the screen with high-frequency vibration. When the materials vibration with low-frequency , superimposed on the ultrasonic vibration, screen mesh can prevent clogging, but also to improve the output and quality screening, to achieve the purpose of efficient screening and cleaning screen surface, ultra-fine powder is easy to sieve. The system introduces a low-amplitude and high-frequency ultrasonic vibration wave (mechanical wave) on the screen based on the traditional vibrating screen to improve the screening performance of the ultrafine particles. Particularly suitable for high value-added fine split users.

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, other industries, etc.

KS series vacuum feeder, also known as vacuum conveyor, is a device that transports powder materials through gas generation, it is a type of gas transportation. It is suitable for many industries such as medicine, food, chemical industry, metallurgy, and building materials. It is designed for the closed transportation of various powder materials, improves the cleanliness of materials, and can meet the various transportation needs of different customers.

Medicine, food, chemical industry, metallurgy, building materials and other industries

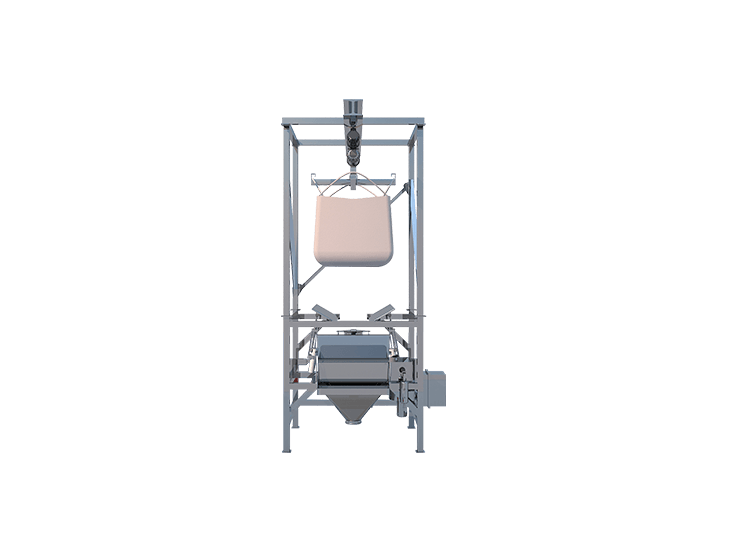

This equipment is suitable for unpacking and unloading dry powder and granular materials such as plastic resin and food additives in large bags in the fields of plastics, rubber, food, medicine, chemical industry, etc.

Pharmaceutical, food, chemical, metallurgy, building materials and other industries

This salt crusher machine toothed model works largely with shear force and less crushing. Crushing gap can be adjusted within certain range.

This machine is composed by frame, gear roller, transmission device and gear roller gap adjustment device and so on. Adopting alternating current motor to drive the coarse broken tooth roller on the both sides by the strong triangular belt respectively, so that the coarse broken tooth roller rotates in opposite directions. After the material enters the crushing chamber from the inlet, the two coarse roller is broken by a variety of different combinations broken which are rotated at a high speed, the partical size can be reach to around 6mm after fine broken, the size of particle size can be adjusted by fine teeth roller gap to complete.

Understand the industry and better understand your needs

With its continuously innovative technology and craftsmanship, effective quality control system, complete pre-sales and after-sales systems, and personalized customized solutions, Gaofu is deeply favored and praised by customers at home and abroad.

The products are exported to many countries and regions around the world, such as North America, Germany, Japan, Argentina, Brazil, Russia and other 100 countries and regions.

Learn more

60,000㎡ production base, modern factory facilities, multiple production lines and various general (special) manufacturing equipment, accumulated 10,000+ industry solution experience, can easily meet various production customization needs

Established a technology research center with more than 30 R&D personnel. It has successfully applied for 500+ national patents and independently developed electromechanical equipment to achieve truly independent research and development from the source.

Strictly implement the international quality standard system and industry standard requirements. From raw material procurement to product delivery, every link uses scientific and technological processes, pays attention to every detail, and strictly controls product quality.

Before sales, we provide personalized customized solutions based on actual needs and conditions; during sales, dedicated personnel will follow up on needs one-on-one to ensure equipment delivery; after sales, we provide 7*24 hours all-weather service to solve customer problems in a timely manner

Gaofu not only serves the world's top 500 companies

Zoomlion Heavy Industry Co., Ltd. was founded in 1992 and is headquartered in Zoomlion Science and Technology Park, Lugu High-tech Zone, Changsha. It is mainly engaged in the R&D and manufacturing of major high-tech equipment required for infrastructure construction such as construction engineering, energy engineering, environmental engineering, and transportation engineering. , is a global enterprise that continues to innovate.

Liming Heavy Industry is a well-known brand in my country’s machinery manufacturing industry. The brand is affiliated to Henan Liming Heavy Industry Technology Co., Ltd. Liming Heavy Industry Technology is a joint-stock enterprise that mainly produces large and medium-sized series of crushers, sand making machines, and grinding mills, integrating R&D, production, and sales.

Focus on Gaofu, Learn about real-time news

Recently, the Ministry of Industry and Information Technology announced the “List of Specialized, Special and New ‘Little Giant’ Enterprises Recommended for Support”. Xinxiang Gaofu Machinery Co., Ltd. was selected. The selected companies are all “vanguards” of technological innovation in their respective fields.

Xinxiang Gaofu Machinery Co., Ltd. was established in 1982. Its main business is the development and sales of vibration machinery, screening equipment, conveying equipment, coal crushing machinery and filtering equipment. On March 25, 2016, Gaofu shares were listed on the New Third Board (stock code: 836946).

Recently, Xinxiang Gaofu Machinery Co., Ltd. (hereinafter referred to as “Gaofu Machinery”) has achieved remarkable results in the global vibrating screen market. With its excellent…

What we have to do is to control quality strictly .

To understand all the needs of customers.

As long as there is business there will be competition, we have to do is how to stand out in the competition!

Face the fierce market competition and customer different levels needs, Gaofu companies always insist constant innovation, all for the sake of customers, in order to meet the changing needs of customers! With the popularity of vibration screen machine, more and more industries are beginning to use vibrating screen.

Coal crusher is mainly suitable for coal-fired power plants, because the boiler coal is usually raw coal which is not classify, most of the raw coal particle size does not meet the coal requirements of the boiler, need to crush, coal-fired power plant coal handling system should set crusher , The coal broken into a certain size, to meet the requirements of the boiler combustion.

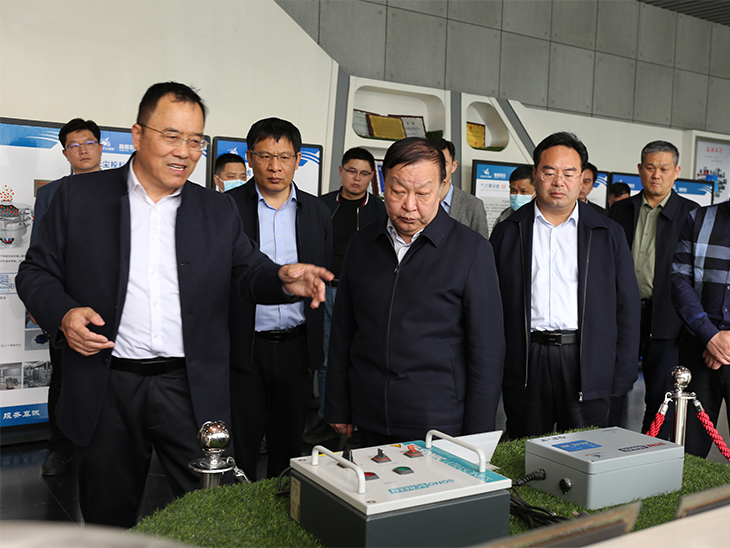

On April 14, Qi Wenhua, deputy mayor of Xinxiang City, led a team to investigate the construction status of key projects in the city. County leaders Zhu Xiancheng, Li Shaoqing, Xu Wanyin, Zhang Shanbo, Li Dongsheng, and relevant city and county responsible comrades participated in the investigation.

Gaofu editor learned from the Trademark Office of the State Administration for Industry and Commerce that our Xinxiang Gaofu Machinery Co., Ltd….

Gaofu vibrating screen is widely used in granule, powder sieving, and also suitbable for liquid filtration.

Ton Bag Feeding Station is suitable for unpacking and unloading dry powder and granular materials in large bags

Traditional ready-mixed mortar is mainly based on on-site mixing of sand, stone and cement. The product quality is difficult to control, urban roads are seriously polluted, the construction speed is low, and the construction methods are backward. The labor intensity of workers is high, and there are many hidden dangers of safety accidents during construction. Dry-mixed mortar has quickly seized the Chinese new building materials market with its significant advantages in quality, efficiency, economy, and environmental protection.

Qi Wenhua, deputy mayor of Xinxiang City, led a team to investigate Gaofu shares

On April 14, Qi Wenhua, deputy mayor of Xinxiang City, led a team to investigate the construction status of key projects in the city. County leaders Zhu Xiancheng, Li Shaoqing, Xu Wanyin, Zhang Shanbo, Li Dongsheng, and relevant city and county responsible comrades participated in the investigation.

2023/07/07

If you encounter a difficult problem that cannot be solved, fill out the form on the right and Gaofu can provide you with a personalized solution!